Description

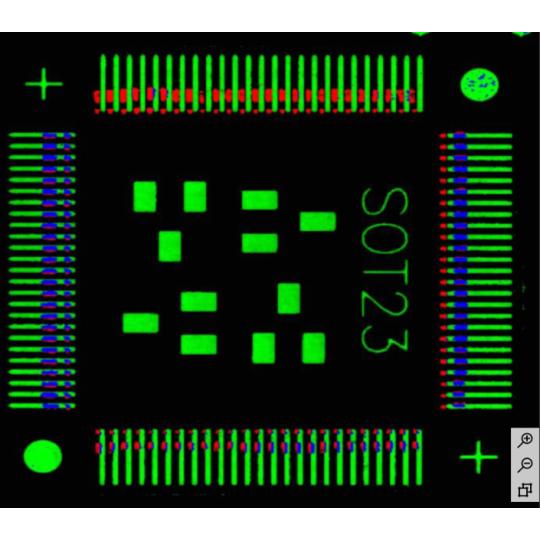

The HR 550 hybrid rework system addresses all users with highest requirements in terms of precision and process safety in electronic assembly rework applications. The HR 550 provides a 1,500 W high-performance hybrid heating element to desolder and solder SMT components up to dimensions of 70 x 70 mm! A 2,400 W infrared bottom heater with three heating zones guarantees homogeneous bottom-side preheating of the complete assembly. Non-contact and contacting temperature sensing directly at the component as well as an optimized process control guarantee ideal removal and installation processes of various component types. A high-precision vacuum pipette, integrated into the units heating head, operates component removal and placement. Stepper motors for the exchangeable hybrid heating head and the vacuum pipette supply exact movement during component desoldering and installation. An integrated force sensor recognizes when component and printed circuit board are contacted. Ergonomically arranged control elements and computer-aided component alignment by means of high-contrast, high-definition camera images are special highlights for the operator. Technical highlights: 1,500 W high-performance hybrid heating element IR bottom heater High-definition cameras for placement and reflow process observation Computer aided component adjustment, digital “split optic” Ergonomically optimized system operation Modern, operator friendly control software The HR 550 is prepared for operation with the Kurtz Ersa DIP&PRINT STATION. The rework system is operated via a newly developed software and ergonomically arranged operating elements on the station.

Specifications

| Type | |

|---|---|

| Length (mm) | |

| Width (mm) | |

| Height (mm) | |

| Weight (kg) | |

| Power | |

| Max, PCB size | |

| Max, Power (W) |

The HR 550 hybrid rework system addresses all users with highest requirements in terms of precision and process safety in electronic assembly rework applications. The HR 550 provides a 1,500 W high-performance hybrid heating element to desolder and solder SMT components up to dimensions of 70 x 70 mm! A 2,400 W infrared bottom heater with three heating zones guarantees homogeneous bottom-side preheating of the complete assembly. Non-contact and contacting temperature sensing directly at the component as well as an optimized process control guarantee ideal removal and installation processes of various component types. A high-precision vacuum pipette, integrated into the units heating head, operates component removal and placement. Stepper motors for the exchangeable hybrid heating head and the vacuum pipette supply exact movement during component desoldering and installation. An integrated force sensor recognizes when component and printed circuit board are contacted. Ergonomically arranged control elements and computer-aided component alignment by means of high-contrast, high-definition camera images are special highlights for the operator. Technical highlights: 1,500 W high-performance hybrid heating element IR bottom heater High-definition cameras for placement and reflow process observation Computer aided component adjustment, digital “split optic” Ergonomically optimized system operation Modern, operator friendly control software The HR 550 is prepared for operation with the Kurtz Ersa DIP&PRINT STATION. The rework system is operated via a newly developed software and ergonomically arranged operating elements on the station.

| Type | |

|---|---|

| Length (mm) | |

| Width (mm) | |

| Height (mm) | |

| Weight (kg) | |

| Power | |

| Max, PCB size | |

| Max, Power (W) |