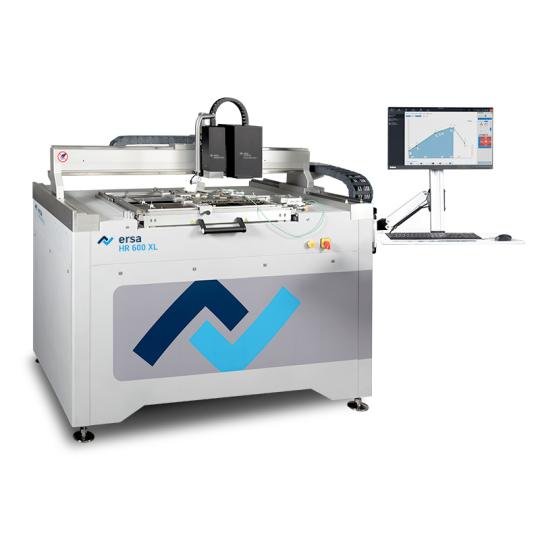

Ersa – HR600XL

With the Ersa HR 600 XL it is possible to professionally rework BTC components on big board assemblies

Ersa – HR600XL

With the Ersa HR 600 XL it is possible to professionally rework BTC components on big board assemblies

Description

Boasting a heated area of 24 x 24 inch and a PCB thickness of up to 10 mm opens up rework capabilities in the segments of telecommunication, network and infrastructure.

The bottom side IR Matrix heater™ with a total power of 15 kW consists of 25 individual controllable heating elements. For each application the ideal heat distribution can be set.

The highly efficient 800 W hybrid heating head executes the component desoldering or installation from chip resistors to 60 x 60 mm (2.36 x 2.36 inch) tall BGAs or sockets. This size can be increased to 150 x 80 mm with an optional extra large heater. Like in its little brother HR 600/2 automatic and precise component adjustment by means of image processing and an accurate axis system provide exact component placement down to (01005 chips).

Large PCB inserted in holder with bottom side support and 800 W hybird heater Large metallic BGA on HR 600 XL light dome

Optional extra large hybrid heater with 150 x 80 mm

It is ready to use the Ersa Dip&Print station to prepare components with exact amounts of flux or solder paste previous to soldering.

Process control and documentation is operated by the newly introduced HRSoft 2 software package.

Specifications

| Type | |

|---|---|

| Length (mm) | |

| Width (mm) | |

| Height (mm) | |

| Weight (kg) | |

| Power | |

| Max, PCB size | |

| Max, Power (W) |

Boasting a heated area of 24 x 24 inch and a PCB thickness of up to 10 mm opens up rework capabilities in the segments of telecommunication, network and infrastructure.

The bottom side IR Matrix heater™ with a total power of 15 kW consists of 25 individual controllable heating elements. For each application the ideal heat distribution can be set.

The highly efficient 800 W hybrid heating head executes the component desoldering or installation from chip resistors to 60 x 60 mm (2.36 x 2.36 inch) tall BGAs or sockets. This size can be increased to 150 x 80 mm with an optional extra large heater. Like in its little brother HR 600/2 automatic and precise component adjustment by means of image processing and an accurate axis system provide exact component placement down to (01005 chips).

Large PCB inserted in holder with bottom side support and 800 W hybird heater Large metallic BGA on HR 600 XL light dome

Optional extra large hybrid heater with 150 x 80 mm

It is ready to use the Ersa Dip&Print station to prepare components with exact amounts of flux or solder paste previous to soldering.

Process control and documentation is operated by the newly introduced HRSoft 2 software package.

| Type | |

|---|---|

| Length (mm) | |

| Width (mm) | |

| Height (mm) | |

| Weight (kg) | |

| Power | |

| Max, PCB size | |

| Max, Power (W) |