Komax - Microlab 35

QT-99f44174

MicroLab 35 : Micrographie Fiable le Contrôle Qualité

Besoin d'un devis, d'une installation ou d'une formation ?

Call +32 (0)14 42 44 01 or contactez nous

Description

Le laboratoire de micrographie MicroLab 35 permet un contrôle rapide et précis des sertissages B de 0,5 à 3,0 mm dans le cadre de tests de qualité en série. Il garantit une assurance qualité complète, offrant ainsi un avantage concurrentiel.

Conçu pour une Analyse Précise des Sertissages

- Transport automatique pour un traitement efficace.

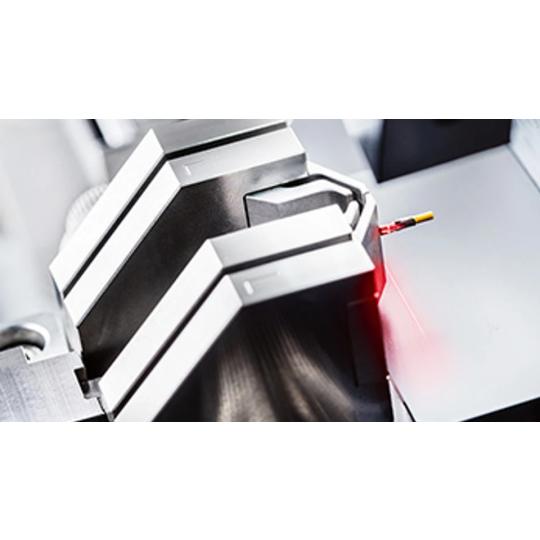

- Alignement précis de la coupe grâce à un microscope et un laser de guidage.

- Unité de gravure intégrée et module de grossissement pour une inspection détaillée.

- Processus parallèles permettant des temps de traitement réduits et une production continue de microphotos.

- Processus de coupe et de polissage en deux étapes, sans repositionnement, pour une précision maximale.

Avantages Clés

✅ Positionnement facile grâce au laser de guidage.

✅ Gain de temps : Coupe et polissage en une seule opération.

✅ Production continue de micrographies grâce à des processus parallèles optimisés.

Le MicroLab 35 est la solution idéale pour un contrôle qualité avancé, permettant une analyse efficace et reproductible des connexions serties.

Specifications

| Processing area (max. terminal Ø) | min. 0.3 mm - max. 3 mm |

| Dimensions (L x W x H) | 1.100 x 320 x 485 mm |

| Weight | 90 kg |

| Electrical connection | 100 - 240 V AC, 50/60 Hz |

Downloads

Le laboratoire de micrographie MicroLab 35 permet un contrôle rapide et précis des sertissages B de 0,5 à 3,0 mm dans le cadre de tests de qualité en série. Il garantit une assurance qualité complète, offrant ainsi un avantage concurrentiel.

Conçu pour une Analyse Précise des Sertissages

- Transport automatique pour un traitement efficace.

- Alignement précis de la coupe grâce à un microscope et un laser de guidage.

- Unité de gravure intégrée et module de grossissement pour une inspection détaillée.

- Processus parallèles permettant des temps de traitement réduits et une production continue de microphotos.

- Processus de coupe et de polissage en deux étapes, sans repositionnement, pour une précision maximale.

Avantages Clés

✅ Positionnement facile grâce au laser de guidage.

✅ Gain de temps : Coupe et polissage en une seule opération.

✅ Production continue de micrographies grâce à des processus parallèles optimisés.

Le MicroLab 35 est la solution idéale pour un contrôle qualité avancé, permettant une analyse efficace et reproductible des connexions serties.

| Type | Micrograph Laboratories |

|---|