Komax - Cut and Strip machine Kappa 340

KMX-0406001

La Kappa 340 assure un traitement précis des surfaces de câbles inégales, des câbles de batterie, multicœurs, HV et de capteurs, ainsi que des isolants durs, rigides, épais et fins (*).

Komax - Cut and Strip machine Kappa 340

KMX-0406001

La Kappa 340 assure un traitement précis des surfaces de câbles inégales, des câbles de batterie, multicœurs, HV et de capteurs, ainsi que des isolants durs, rigides, épais et fins (*).

Besoin d'assistance, d'installation et/ou de formation ?

Appelez-nous +32 (0)14 42 44 01 ou contactez nous

Description

Les machines Kappa peuvent traiter de nombreux câbles en dehors de la plage de sections spécifiée. Il peut ne pas être possible de traiter des câbles extrêmement durs et rigides, même s’ils sont dans la plage spécifiée. En cas de doute, nous serons heureux de vous fournir des échantillons pour vos câbles.

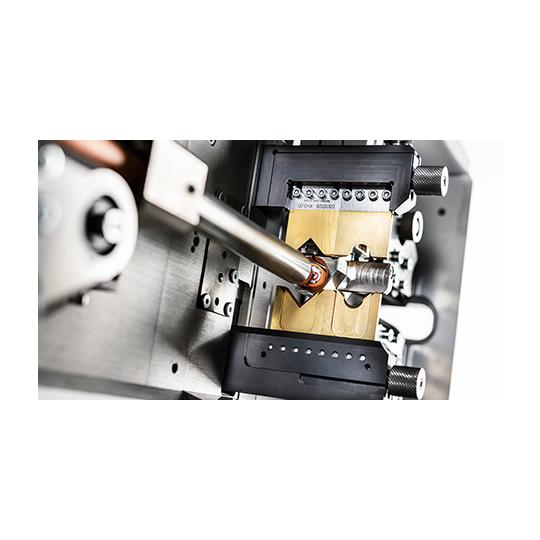

La machine de découpe et de dénudage Kappa 340 est équipée pour une large gamme d’applications et offre des performances élevées. La machine dispose des caractéristiques suivantes :

- Tête de coupe double : Traite des câbles de 0,22 à 70 mm² et des câbles plats jusqu’à 16 mm de large.

- Unité de coupe rotative (optionnelle) : Pour des temps de changement rapides et des coupes rondes précises.

- Traitement efficace des câbles : Avec des couteaux de rotation, de coupe et de dénudage et un entraînement à courroie avec couple élevé et bonne prise, la Kappa 340 peut traiter efficacement même les câbles difficiles à des vitesses allant jusqu’à 4 m/s.

- Logiciel TopWin : Pour générer des listes de matériaux, des séquences et des faisceaux de câbles. Il permet également l’étiquetage des câbles, la connexion au réseau de l’entreprise et l’impression des lettres de transport.

Options :

- Tête de coupe double avec lame de formage pour un traitement précis

- Tête de coupe double optionnelle avec unité de séparation

- Tête de coupe double optionnelle avec lame en V et lame en forme de V

- Entraînement à courroie avec couple élevé et longue surface de support

Specifications

| Wire cross-section, stranded wires | 0.22 – 70 mm² / AWG 24 – 2/0 (*) |

| Max. outer diameter | 16 mm |

| Length accuracy | Length tolerance (± (0.2 % + 1 mm)) |

| Flat wire processing | Optional 16mm |

| Wire length range (short mode possible) | 1 – 800.000 mm |

| Rotary incision | Standard programmable incision diameter on one or more wire layers |

| Max. wire transport speed | 4.0 m/s |

| Wire transport system | Multiple supported belt drive |

| Electrical connection | 110/230 VAC ±10% - 50/60 Hz - 650 VA |

| Dimensions (W × H × D) | 760 × 380 × 1.005 mm |

| Weight | 75 kg |

Les machines Kappa peuvent traiter de nombreux câbles en dehors de la plage de sections spécifiée. Il peut ne pas être possible de traiter des câbles extrêmement durs et rigides, même s’ils sont dans la plage spécifiée. En cas de doute, nous serons heureux de vous fournir des échantillons pour vos câbles.

La machine de découpe et de dénudage Kappa 340 est équipée pour une large gamme d’applications et offre des performances élevées. La machine dispose des caractéristiques suivantes :

- Tête de coupe double : Traite des câbles de 0,22 à 70 mm² et des câbles plats jusqu’à 16 mm de large.

- Unité de coupe rotative (optionnelle) : Pour des temps de changement rapides et des coupes rondes précises.

- Traitement efficace des câbles : Avec des couteaux de rotation, de coupe et de dénudage et un entraînement à courroie avec couple élevé et bonne prise, la Kappa 340 peut traiter efficacement même les câbles difficiles à des vitesses allant jusqu’à 4 m/s.

- Logiciel TopWin : Pour générer des listes de matériaux, des séquences et des faisceaux de câbles. Il permet également l’étiquetage des câbles, la connexion au réseau de l’entreprise et l’impression des lettres de transport.

Options :

- Tête de coupe double avec lame de formage pour un traitement précis

- Tête de coupe double optionnelle avec unité de séparation

- Tête de coupe double optionnelle avec lame en V et lame en forme de V

- Entraînement à courroie avec couple élevé et longue surface de support

| Type | Cut & Strip |

|---|---|

| Max cross section (mm²) | 70 |