Komax - Fully Automatic Wire Processing Machine Gamma 450

KMX-0373000

Machine Automatique de Traitement des Câbles Compacte

Komax - Fully Automatic Wire Processing Machine Gamma 450

KMX-0373000

Machine Automatique de Traitement des Câbles Compacte

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

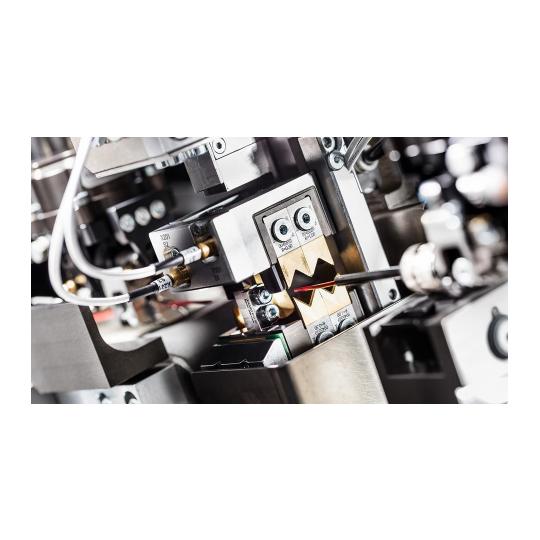

La Gamma 450 est une machine automatique de traitement des câbles compacte qui effectue des opérations de sertissage et de scellement des deux côtés pour des câbles avec des sections transversales de 0,13 à 4 mm². Malgré son design compact, la machine offre des performances impressionnantes. Elle propose une surveillance de qualité entièrement intégrée avec CFA/CFA+, ACD et Q1250 et peut être adaptée avec des modules optionnels pour répondre à des exigences élevées et tournées vers l’avenir.

Caractéristiques principales :

- Configuration flexible : La machine peut être configurée individuellement sur quatre stations pour répondre aux besoins spécifiques du processus.

- Applications dans l’industrie automobile : La Gamma 450 est particulièrement adaptée à l’industrie automobile et à ses exigences évolutives pour des machines durables.

- Conception ergonomique : La conception ergonomique et les flux de travail logiques augmentent l’efficacité économique et facilitent l’utilisation de la machine.

- Système de changement rapide : Les bobines de pince et les outils de sertissage peuvent être remplacés pendant le fonctionnement grâce au système de changement rapide pour les outils STC et les bobines de pince.

- Installation rapide et alimentation en fil : Aucun élément de guidage n’est nécessaire pour une installation rapide et une alimentation en fil efficace.

- Accessoires optionnels : Des outils stationnaires et des systèmes de changement rapide pour les bobines de pince peuvent être ajoutés.

- Surveillance de la coupe et de la qualité avancée : Le porte-lame à double lame avec tête double offre une surveillance de précision ACD, et la surveillance optique de la qualité avec le Q1250 garantit un contrôle fiable de la qualité.

- Facilité d’utilisation : Le module peut être facilement configuré, augmentant ainsi la convivialité.

Specifications

| Wire cross-sections | 0.13 – 4 mm² (AWG 26 – AWG 12) (*) |

| Wire draw-in speed | max. 8m/s belt drive |

| Wire outer diameter | max. 3.9 mm |

| Length range | 60 – 65.000 mm (Repeat accuracy ± (0.2 % + 1 mm) - Deposit length > 8 m on request) / optional 33 – 60 mm |

| Full strip | 0.1 – 16.5 mm (*) / With optional double blade up to 35 mm |

| Partial strip | 0.1 – 16 mm (*) / With optional double blade up to 21 mm (S1) and 34.5 mm (S2) |

| Crimp force | 1 – 22 kN |

| Process modules | Side 1 and side 2: 2 stations |

| Noise level | < 75 dB (without crimp tool) |

| Electrical connection | 3 × 208 – 480 V; 50/60 Hz; 2.5 kVA or 3 × 400 V, 50/60 Hz, 2.5 kVA |

| Compressed-air connection | 5 – 8 bar |

| Recommended operating pressure | 6 ± 0.5 bar |

| Air consumption of crimp /crimp | < 6 m³/h |

| Air consumption of seal crimp / seal crimp | < 9 m³/h |

| Weight (incl. 2 crimp modules + 2 seal modules) | 920 kg |

Downloads

La Gamma 450 est une machine automatique de traitement des câbles compacte qui effectue des opérations de sertissage et de scellement des deux côtés pour des câbles avec des sections transversales de 0,13 à 4 mm². Malgré son design compact, la machine offre des performances impressionnantes. Elle propose une surveillance de qualité entièrement intégrée avec CFA/CFA+, ACD et Q1250 et peut être adaptée avec des modules optionnels pour répondre à des exigences élevées et tournées vers l’avenir.

Caractéristiques principales :

- Configuration flexible : La machine peut être configurée individuellement sur quatre stations pour répondre aux besoins spécifiques du processus.

- Applications dans l’industrie automobile : La Gamma 450 est particulièrement adaptée à l’industrie automobile et à ses exigences évolutives pour des machines durables.

- Conception ergonomique : La conception ergonomique et les flux de travail logiques augmentent l’efficacité économique et facilitent l’utilisation de la machine.

- Système de changement rapide : Les bobines de pince et les outils de sertissage peuvent être remplacés pendant le fonctionnement grâce au système de changement rapide pour les outils STC et les bobines de pince.

- Installation rapide et alimentation en fil : Aucun élément de guidage n’est nécessaire pour une installation rapide et une alimentation en fil efficace.

- Accessoires optionnels : Des outils stationnaires et des systèmes de changement rapide pour les bobines de pince peuvent être ajoutés.

- Surveillance de la coupe et de la qualité avancée : Le porte-lame à double lame avec tête double offre une surveillance de précision ACD, et la surveillance optique de la qualité avec le Q1250 garantit un contrôle fiable de la qualité.

- Facilité d’utilisation : Le module peut être facilement configuré, augmentant ainsi la convivialité.

| Type | Crimp To Crimp |

|---|---|

| Max cross section (mm²) | 4 |