Fritsch SMT - Manual Pick & Place Machine MP904

FRI-90441001

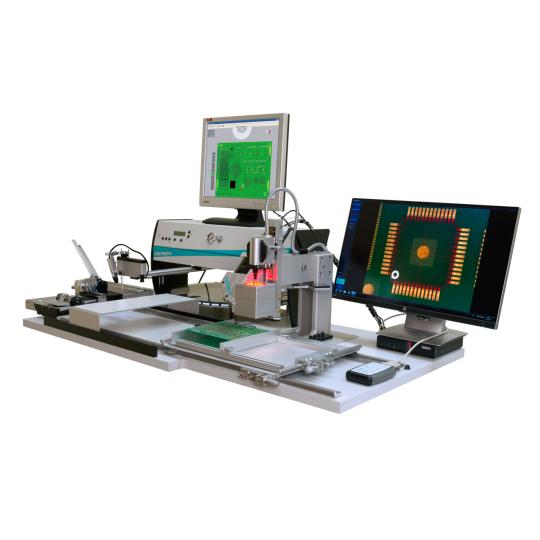

La station d’assemblage multitâche MP904 offre un confort ergonomique pour la distribution et l’assemblage de prototypes et de séries moyennes.

Fritsch SMT - Manual Pick & Place Machine MP904

FRI-90441001

La station d’assemblage multitâche MP904 offre un confort ergonomique pour la distribution et l’assemblage de prototypes et de séries moyennes.

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

Le MP904 combine la simplicité et la flexibilité d’utilisation d’un manipulateur avec les normes élevées de précision de placement des composants à pas fin.

Le guidage fluide inégalé de la tête de montage permet de placer les CMS avec précision. Lorsque la pipette entre en contact avec les composants, le vide s’active automatiquement et se désactive lors du placement.

Le système de vision spécialisé permet un placement optimal des composants BGA et QFN. La gamme d’éléments d’assemblage commence par la puce 0201 et se termine par les composants à pas fin et BGA.

Specifications

| Max. dimensions | 1200 x 700 mm |

| Max. PCB size | 340 x 250 mm |

| Max. placement area | 340 x 250 mm |

Le MP904 combine la simplicité et la flexibilité d’utilisation d’un manipulateur avec les normes élevées de précision de placement des composants à pas fin.

Le guidage fluide inégalé de la tête de montage permet de placer les CMS avec précision. Lorsque la pipette entre en contact avec les composants, le vide s’active automatiquement et se désactive lors du placement.

Le système de vision spécialisé permet un placement optimal des composants BGA et QFN. La gamme d’éléments d’assemblage commence par la puce 0201 et se termine par les composants à pas fin et BGA.

| Type | Manual Mounter |

|---|