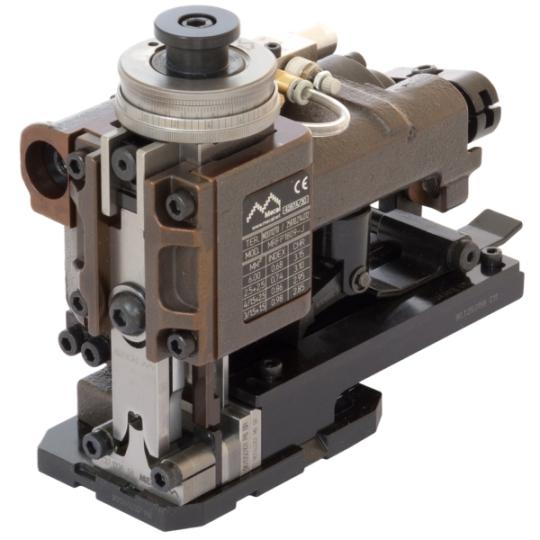

Mecal - Restyling Pneumatic Applicator

CS-fd916882

L’applicateur pneumatique Restyling

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

L’applicateur pneumatique Restyling est un mini-applicateur pour manchons couplés, avec une épaisseur < 1,2 mm, une distance de pince > 27 mm (si la distance est inférieure à 27 mm, une version avec système d’alimentation pneumatique peut être fournie sur demande), et une section de câble entre 0 et 10 mm².

Caractéristiques principales :

- Système d’alimentation latérale pneumatique : Déroule les manchons couplés de gauche à droite sur un rouleau.

- Tête de régulation continue ou à quatre pads : Disponible en option.

- Compteur de cycles 7 chiffres non réinitialisable.

- Compatibilité de montage : Peut être monté sur toute presse à sertir avec une hauteur de sertissage de 135,8 mm ± 0,02 mm (mesurée depuis la plaque de base du mini-applicateur jusqu’à la jonction en T de la presse au point mort inférieur).

- Utilisation polyvalente : Peut être utilisé manuellement (pour presse de table) ou automatiquement (pour machines de coupe et de dénudage).

- Documentation technique complète : Inclut toutes les informations nécessaires pour une utilisation sûre et un entretien correct.

- Étude de capacité sur demande : Comprend une photo d’un manchon serti coupé en section.

Améliorations de la famille Restyling :

- Aambeeld remplaçable : L’aambeeld peut être remplacé sans retirer l’applicateur de la presse. L’aambeeld est composé de deux parties, câble et isolation, permettant de remplacer uniquement la partie usée.

- Plaque de base plus épaisse : La plaque de base du mini-applicateur est plus épaisse pour une plus grande robustesse.

- Remplacement des sertisseurs facilité : Le corps du mini-applicateur permet de remplacer les sertisseurs sans retirer le vérin ou l’applicateur de la presse.

- Système de réglage de l’écartement plus facile à utiliser : Le centrage du manchon sur l’aambeeld est désormais encore plus facile et est clairement illustré dans la documentation technique détaillée.

- Produit sous un système de gestion de la qualité certifié ISO 9001 (TÜV).

Specifications

| Crimping height | 135,8 mm |

| Stroke | 40 / 30 mm |

| Terminal pitch | > 27 mm |

| Max. stroke | 35 mm |

| Terminal thickness | < 1,2 mm |

| Wire section | max 10 mm² |

| Feeding system | air pressure 5/6 bar |

| Weight | 4,1 kg |

| Dimensions (WxHxD) | 140 x 145 x 105 mm |

| Options | Continuous regulation head, 0,01 mm resolution, 2,7 mm range |

L’applicateur pneumatique Restyling est un mini-applicateur pour manchons couplés, avec une épaisseur < 1,2 mm, une distance de pince > 27 mm (si la distance est inférieure à 27 mm, une version avec système d’alimentation pneumatique peut être fournie sur demande), et une section de câble entre 0 et 10 mm².

Caractéristiques principales :

- Système d’alimentation latérale pneumatique : Déroule les manchons couplés de gauche à droite sur un rouleau.

- Tête de régulation continue ou à quatre pads : Disponible en option.

- Compteur de cycles 7 chiffres non réinitialisable.

- Compatibilité de montage : Peut être monté sur toute presse à sertir avec une hauteur de sertissage de 135,8 mm ± 0,02 mm (mesurée depuis la plaque de base du mini-applicateur jusqu’à la jonction en T de la presse au point mort inférieur).

- Utilisation polyvalente : Peut être utilisé manuellement (pour presse de table) ou automatiquement (pour machines de coupe et de dénudage).

- Documentation technique complète : Inclut toutes les informations nécessaires pour une utilisation sûre et un entretien correct.

- Étude de capacité sur demande : Comprend une photo d’un manchon serti coupé en section.

Améliorations de la famille Restyling :

- Aambeeld remplaçable : L’aambeeld peut être remplacé sans retirer l’applicateur de la presse. L’aambeeld est composé de deux parties, câble et isolation, permettant de remplacer uniquement la partie usée.

- Plaque de base plus épaisse : La plaque de base du mini-applicateur est plus épaisse pour une plus grande robustesse.

- Remplacement des sertisseurs facilité : Le corps du mini-applicateur permet de remplacer les sertisseurs sans retirer le vérin ou l’applicateur de la presse.

- Système de réglage de l’écartement plus facile à utiliser : Le centrage du manchon sur l’aambeeld est désormais encore plus facile et est clairement illustré dans la documentation technique détaillée.

- Produit sous un système de gestion de la qualité certifié ISO 9001 (TÜV).

| Type | Applicator |

|---|