Komax - Stripping Crimping Machine Delta 240

KMX-0410240

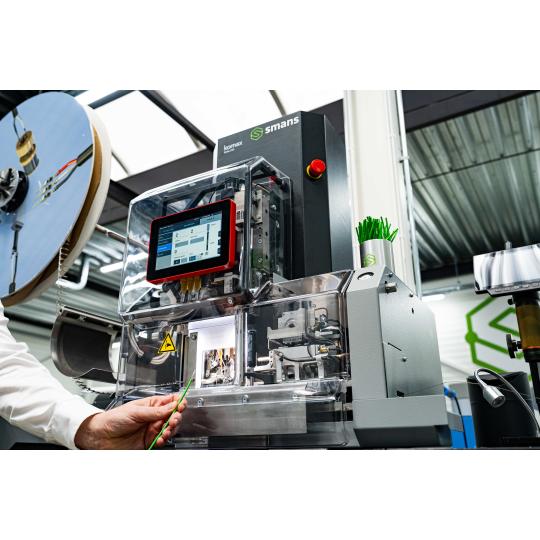

Delta 240 : Machine de Sertissage Semi-Automatique avec Surveillance de la Force de Sertissage et Réglage Automatique de la Hauteur de Sertissage

Komax - Stripping Crimping Machine Delta 240

KMX-0410240

Delta 240 : Machine de Sertissage Semi-Automatique avec Surveillance de la Force de Sertissage et Réglage Automatique de la Hauteur de Sertissage

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

La Delta 240 est une machine de sertissage et de dénudage semi-automatique avec réglage automatique de la hauteur de sertissage et surveillance avancée de la force de sertissage. Cette machine est conçue pour une grande précision et qualité des processus, garantissant une excellente répétabilité.

Caractéristiques principales :

- Réglage automatique de la hauteur de sertissage : Garantit des résultats constants sans réglages manuels.

- Surveillance de la force de sertissage CFA/CFA+ : Détecte de manière fiable les brins manquants, les câbles incorrects ou l’isolation pendant le processus de sertissage, garantissant la qualité.

- Mécanique précise : Assure une haute répétabilité et une qualité de processus fiable.

- Interface conviviale : L’interface graphique permet une utilisation intuitive, avec une aide contextuelle, la sélection de la langue et des droits d’utilisateur.

- Entrée minimale de l’opérateur : Grâce à la programmation, les paramètres sont reproductibles, minimisant l’intervention de l’opérateur.

- Capacité de stockage accrue : La capacité de stockage a été étendue à 5 000 articles.

- Extensions optionnelles : La Delta 240 peut être équipée d’un coupeur à mauvais contact, d’une unité d’extraction et d’une fonction de séquencement pour des fonctionnalités supplémentaires.

Logiciel QCENTER :

- Intégration des appareils de mesure : Le logiciel QCenter intègre les appareils de mesure de la hauteur de sertissage et de la force d’extraction dans le processus de production et garantit que la production commence uniquement lorsque les valeurs cibles et réelles correspondent.

- Prévention des erreurs de production : L’entrée manuelle des données n’est plus nécessaire et la production commence uniquement lorsque les valeurs mesurées se situent dans les tolérances requises.

- Intégration optionnelle du code-barres : Un scanner de code-barres peut être intégré pour utiliser les appareils de mesure de la hauteur de sertissage et de la force d’extraction, tels que Komax 341 ou Q1210, sur jusqu’à 20 sertisseuses.

- Transmission des données en temps réel vers MES : Les données de mesure peuvent être transmises en temps réel à un MES (Système d’exécution de la fabrication) via l’interface MIKO pour le stockage et l’évaluation.

- Génération automatique de rapports : Komax Print génère automatiquement un rapport de mesure lors de la mise en production et le stocke localement.

Specifications

| Cross-section range | 0.03 – 6.6 mm² (AWG 32 – 9) |

| Storage | 5000 articles, 1000 wires, 500 terminals |

| Max. crimp force | 20 kN |

| Stroke | 10 - 40 mm |

| Shut height | standard 135.8 mm / on request 118.3 - 174.8 mm |

| Stroke repeat accuracy | 0.006 mm |

| Crimp height adjustment | automatic, programmable + 0.2 mm ... - 0.8 mm |

| Split cycle for closed terminals | 1 - 20 mm |

| Strip length | 0.1 - 13 mm |

| Cycle time | crimp < 0.8 s, strip + crimp < 1.8 s |

| Electrical connection | 1 × 230 VAC, 50/60 Hz, 180 – 260 V, 1 × 115 VAC, 60 Hz, 92-130 V, 2000 VA |

| Compressed-air connection | 4 – 6 bar |

| Dimensions (WxHxD) | 700 x 750 x 500 mm |

| Weight | approx. 110 kg |

La Delta 240 est une machine de sertissage et de dénudage semi-automatique avec réglage automatique de la hauteur de sertissage et surveillance avancée de la force de sertissage. Cette machine est conçue pour une grande précision et qualité des processus, garantissant une excellente répétabilité.

Caractéristiques principales :

- Réglage automatique de la hauteur de sertissage : Garantit des résultats constants sans réglages manuels.

- Surveillance de la force de sertissage CFA/CFA+ : Détecte de manière fiable les brins manquants, les câbles incorrects ou l’isolation pendant le processus de sertissage, garantissant la qualité.

- Mécanique précise : Assure une haute répétabilité et une qualité de processus fiable.

- Interface conviviale : L’interface graphique permet une utilisation intuitive, avec une aide contextuelle, la sélection de la langue et des droits d’utilisateur.

- Entrée minimale de l’opérateur : Grâce à la programmation, les paramètres sont reproductibles, minimisant l’intervention de l’opérateur.

- Capacité de stockage accrue : La capacité de stockage a été étendue à 5 000 articles.

- Extensions optionnelles : La Delta 240 peut être équipée d’un coupeur à mauvais contact, d’une unité d’extraction et d’une fonction de séquencement pour des fonctionnalités supplémentaires.

Logiciel QCENTER :

- Intégration des appareils de mesure : Le logiciel QCenter intègre les appareils de mesure de la hauteur de sertissage et de la force d’extraction dans le processus de production et garantit que la production commence uniquement lorsque les valeurs cibles et réelles correspondent.

- Prévention des erreurs de production : L’entrée manuelle des données n’est plus nécessaire et la production commence uniquement lorsque les valeurs mesurées se situent dans les tolérances requises.

- Intégration optionnelle du code-barres : Un scanner de code-barres peut être intégré pour utiliser les appareils de mesure de la hauteur de sertissage et de la force d’extraction, tels que Komax 341 ou Q1210, sur jusqu’à 20 sertisseuses.

- Transmission des données en temps réel vers MES : Les données de mesure peuvent être transmises en temps réel à un MES (Système d’exécution de la fabrication) via l’interface MIKO pour le stockage et l’évaluation.

- Génération automatique de rapports : Komax Print génère automatiquement un rapport de mesure lors de la mise en production et le stocke localement.

| Type | Applicator Based Crimping |

|---|---|

| Max cross section (mm²) | 4 |