Komax - Wire Assembly Machine Omega 750

KMX-0339000

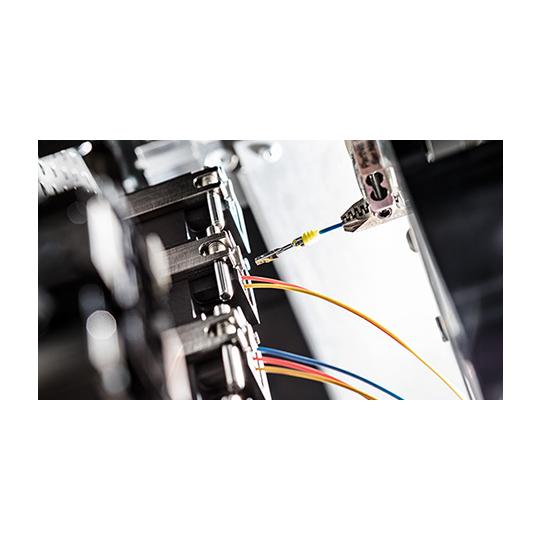

The Omega 750 wire assembly machine can be used to produce wire harnesses of various complexity and to equip them with terminal housings on one or both sides.

Komax - Wire Assembly Machine Omega 750

KMX-0339000

The Omega 750 wire assembly machine can be used to produce wire harnesses of various complexity and to equip them with terminal housings on one or both sides.

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

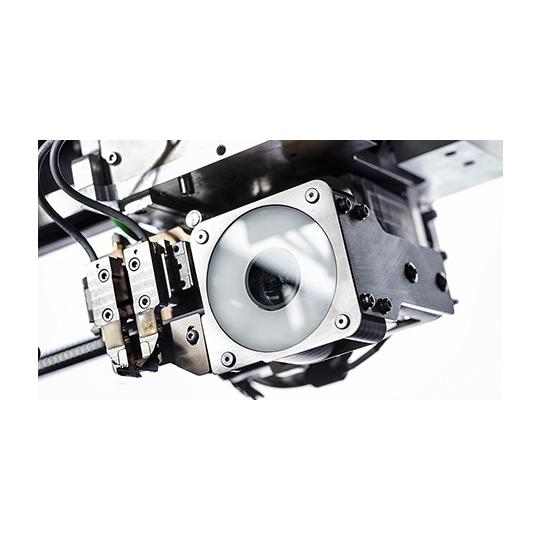

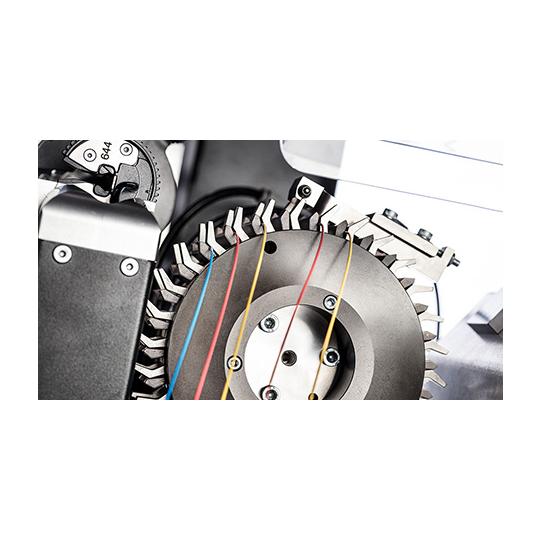

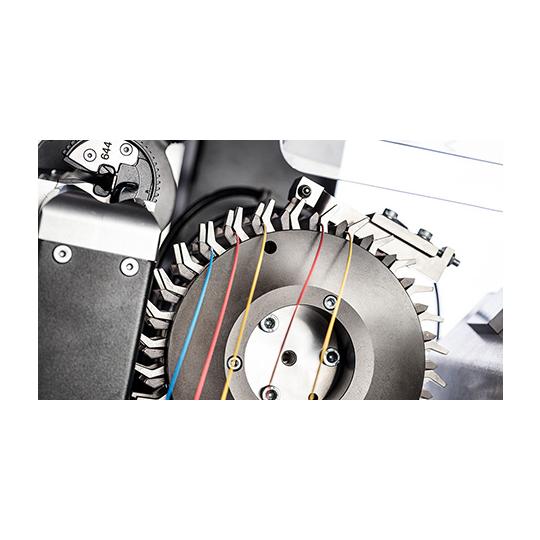

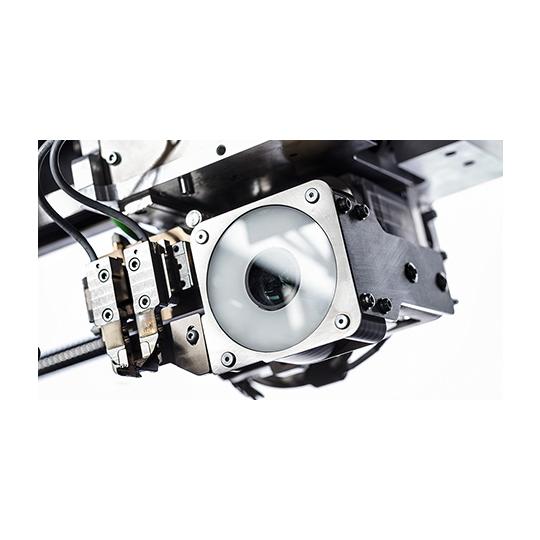

The Omega 750 wire assembly machine can be used to produce wire harnesses of various complexity and to equip them with terminal housings on one or both sides. (*) Piece output is dependent on wire length and housing/terminal combinations. (**) Dependent on wire harness structure (***) Certain extremely hard, tough wires may not be able to be processed, even if they are within the indicated cross-sectional area. If in doubt, we are happy to provide you with samples of your wires. Eight modules can be installed on the Omega 750. This means that autonomous wire harnesses can be created in a short production time. The Omega series is manufactured for automated wire harness production. Regardless of the operator, the quality of the end product is ensured: A high-precision force sensor monitors the insertion process of up to 36 different wires and the precise locking of the terminal part in the housing. The individual parameters are automatically compared. Supported by a spindle drive, even the smallest components are loaded that could hardly be connected in by hand. The optionally available ACD incision monitoring additionally ensures quality. – Optical terminal measuring system for insertion of various terminals – Extensive wire changer for up to 36 different wires – Three pairs of blades with optional ACD incision monitoring – Special untwisting module for neutralizing twisted wires – Integrated wire storage for more effecient production

Specifications

| Piece output, single-sided and double-sided loading | 1.8 sec per insertion sequence (*) |

| Shortest wire length for single-sided loading | 240 mm |

| Shortest wire length for double-sided jumper connections | 300 – 560 mm (**) |

| Shortest wire length for complex loading | 300 – 780 mm (**) |

| Strip length | up to 25 mm |

| Wire cross-sections | 0.13 – 2.5 mm² (AWG 26 - 14) (***) |

| Outer wire diameter | Max. 4 mm |

| Usable transfer length | 2880 mm, up to eight C1370 crimp modules |

| Usable transfer length extension | 1840 mm up to five additional C1370 crimp modules |

| Wire changer | Max. 36 wires (in increments of six wires) |

| Wire end storage | Rotary storage unit with a maximum of 30 storage spaces |

| Process monitoring (integrated) | Collision monitoring (block chambers), insertion force monitoring, terminal locking monitoring |

| Block feed | Carousel with pallets |

| Pallet system loading area | (W×H) 280 × 200 mm |

| Electrical connection | 3 × 208 – 480 V, 50/60 Hz/10 VA |

| Compressed air connection | 6 bar |

| Air usage | 20 m³/h |

The Omega 750 wire assembly machine can be used to produce wire harnesses of various complexity and to equip them with terminal housings on one or both sides. (*) Piece output is dependent on wire length and housing/terminal combinations. (**) Dependent on wire harness structure (***) Certain extremely hard, tough wires may not be able to be processed, even if they are within the indicated cross-sectional area. If in doubt, we are happy to provide you with samples of your wires. Eight modules can be installed on the Omega 750. This means that autonomous wire harnesses can be created in a short production time. The Omega series is manufactured for automated wire harness production. Regardless of the operator, the quality of the end product is ensured: A high-precision force sensor monitors the insertion process of up to 36 different wires and the precise locking of the terminal part in the housing. The individual parameters are automatically compared. Supported by a spindle drive, even the smallest components are loaded that could hardly be connected in by hand. The optionally available ACD incision monitoring additionally ensures quality. – Optical terminal measuring system for insertion of various terminals – Extensive wire changer for up to 36 different wires – Three pairs of blades with optional ACD incision monitoring – Special untwisting module for neutralizing twisted wires – Integrated wire storage for more effecient production

| Type | With Wire Insertion |

|---|---|

| Max cross section (mm²) | 2.5 |