Komax - Wire Assembly Machine Zeta 630

KMX-0380000

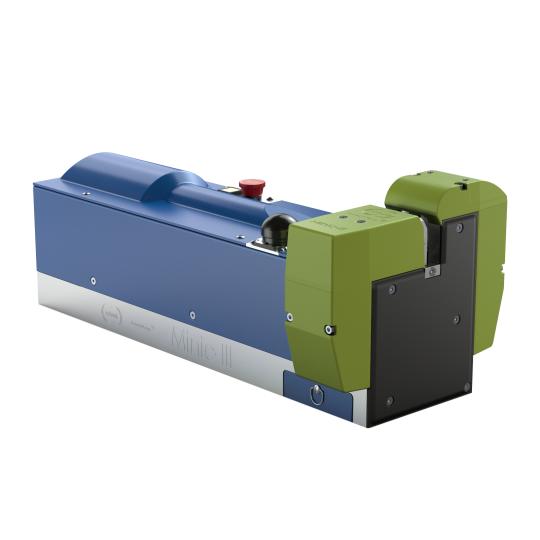

Le Zeta 630 augmente la productivité dans la construction d’armoires électriques grâce à deux modules de traitement à partir d’une taille de lot de 1 et avec jusqu’à 36 fils différents dans le changeur de fils.

Komax - Wire Assembly Machine Zeta 630

KMX-0380000

Le Zeta 630 augmente la productivité dans la construction d’armoires électriques grâce à deux modules de traitement à partir d’une taille de lot de 1 et avec jusqu’à 36 fils différents dans le changeur de fils.

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

La grande variabilité dans la construction des armoires de commande nécessite de nombreux matériaux tels que différents types de fils, bornes ou embouts. La Zeta 630 permet un traitement juste à temps dans la production par lots ou en série de divers fils pour la construction d’armoires sans changement d’équipement, grâce au changeur de fils automatique à 36 positions, au module CM 1/5 GS pour cinq embouts différents et au CM Duo pour les manchons de 4 mm² / 6 mm².

Grâce aux trois paires de lames spéciales, des sections de 0,22 à 6 mm² peuvent être parfaitement traitées en séquence. Les paramètres de traitement sont convertis via TopConvert et envoyés automatiquement par l’interface Komax WPCS directement à la machine sans aucun effort de programmation manuelle.

Points forts

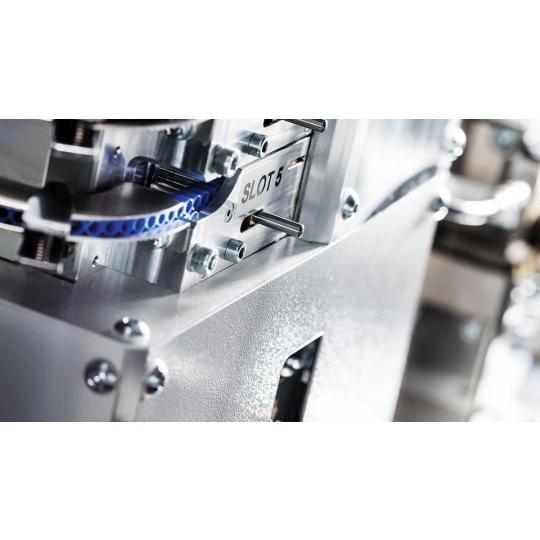

- 36 variantes de fils disponibles dans le changeur de fils : les processus automatisés réduisent le temps de production jusqu’à 50 %. Le changeur de fils automatique fournit jusqu’à 36 fils différents sans changement.

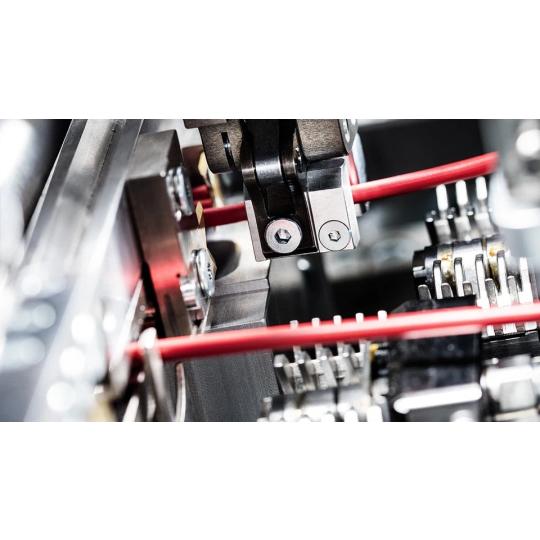

- Traitement précis avec une unité de coupe de haute qualité : l’unité de coupe avec trois paires de lames traite parfaitement les sections de 0,5 à 6 mm² en séquence. Des lames de haute qualité et durables permettent des vitesses de traitement élevées.

- Production par lots ou en séquence sans changement possible : le regroupeur intégré trie les lots et fixe les fils appropriés avec du ruban adhésif en une seule étape. Même les tâches complexes peuvent être réalisées sans grand effort.

- Traitement de jusqu’à 5 embouts différents : le module CM 1/5 GS traite jusqu’à cinq embouts différents. Une production fiable et entièrement automatique garantit une qualité élevée et constante.

- Système de marquage automatique avec deux marqueurs à jet d’encre : le système de marquage automatique pour deux marqueurs à jet d’encre différents étiquette de manière optimale les fils avant leur achèvement, ce qui facilite la logistique et le traitement ultérieur.

Specifications

| Number of stations | 2 |

| Stripping Lengths | up to 25 mm |

| Wire Cross Sections | 0.22 – 6 mm² (AWG 24 – 10) |

| Wire Feed Speed | Maximum of 10 m/s |

| Wire selector | Maximum of 36 cables (in increments of six cables) |

Downloads

La grande variabilité dans la construction des armoires de commande nécessite de nombreux matériaux tels que différents types de fils, bornes ou embouts. La Zeta 630 permet un traitement juste à temps dans la production par lots ou en série de divers fils pour la construction d’armoires sans changement d’équipement, grâce au changeur de fils automatique à 36 positions, au module CM 1/5 GS pour cinq embouts différents et au CM Duo pour les manchons de 4 mm² / 6 mm².

Grâce aux trois paires de lames spéciales, des sections de 0,22 à 6 mm² peuvent être parfaitement traitées en séquence. Les paramètres de traitement sont convertis via TopConvert et envoyés automatiquement par l’interface Komax WPCS directement à la machine sans aucun effort de programmation manuelle.

Points forts

- 36 variantes de fils disponibles dans le changeur de fils : les processus automatisés réduisent le temps de production jusqu’à 50 %. Le changeur de fils automatique fournit jusqu’à 36 fils différents sans changement.

- Traitement précis avec une unité de coupe de haute qualité : l’unité de coupe avec trois paires de lames traite parfaitement les sections de 0,5 à 6 mm² en séquence. Des lames de haute qualité et durables permettent des vitesses de traitement élevées.

- Production par lots ou en séquence sans changement possible : le regroupeur intégré trie les lots et fixe les fils appropriés avec du ruban adhésif en une seule étape. Même les tâches complexes peuvent être réalisées sans grand effort.

- Traitement de jusqu’à 5 embouts différents : le module CM 1/5 GS traite jusqu’à cinq embouts différents. Une production fiable et entièrement automatique garantit une qualité élevée et constante.

- Système de marquage automatique avec deux marqueurs à jet d’encre : le système de marquage automatique pour deux marqueurs à jet d’encre différents étiquette de manière optimale les fils avant leur achèvement, ce qui facilite la logistique et le traitement ultérieur.

| Type | With Tape Bundling |

|---|---|

| Max cross section (mm²) | 6 |