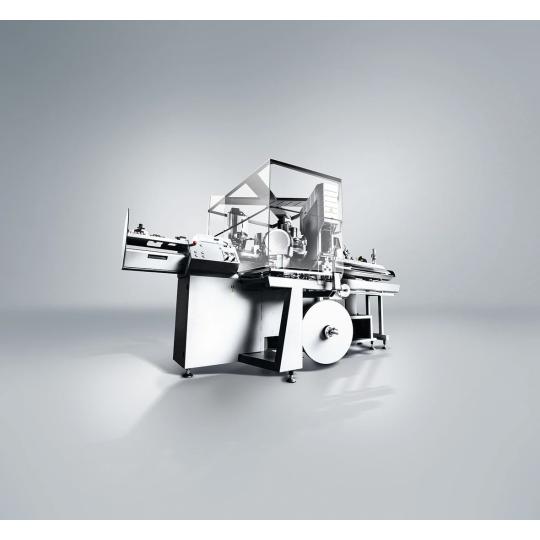

Komax - Fully Automatic Wire Processing Machine Alpha 530

KMX-0341000

Machine Automatique de Traitement des Câbles pour Sertissage et Scellement à Double Face

Komax - Fully Automatic Wire Processing Machine Alpha 530

KMX-0341000

Machine Automatique de Traitement des Câbles pour Sertissage et Scellement à Double Face

Besoin d'un devis, d'une installation ou d'une formation ?

Appelez le +32 (0)14 42 44 01 ou contactez nous

Description

La machine automatique de traitement des câbles Alpha 530 pour sertissage et scellement à double face répond aux normes de qualité élevées pour des sections de câbles de 0,13 à 6 mm². Il est possible de traiter des sections de câbles plus grandes sur demande, et Komax propose des tests de faisabilité pour pré-tester les câbles, en particulier les câbles très durs ou rigides qui peuvent ne pas être traités même s’ils respectent les spécifications.

Caractéristiques principales :

- Configuration flexible : L’Alpha 530 offre des capacités pour des applications spéciales et complexes telles que le double sertissage, l’insertion de bornes et de douilles pour fils, ainsi que le torsionnement et le vernissage des brins.

- Distances courtes entre les stations : La machine dispose de courtes distances entre les stations de sertissage, de câblage et de découpe, ce qui augmente la productivité.

- Zones de travail éclairées par LED : L’éclairage LED dans les zones de travail améliore la visibilité et la sécurité.

- Interface utilisateur intuitive : L’interface séquentielle et configurable individuellement améliore la facilité d’utilisation et accélère les réglages.

- Temps de réglage et de changement rapides : La machine offre des temps de changement rapides, augmentant l’efficacité même avec une production variable.

- Garantie de qualité : La surveillance de la force de sertissage (CFA+/CFA) est intégrée pour le contrôle de la qualité, et une surveillance de précision (ACD) en option peut être ajoutée pour détecter même le plus petit contact entre la lame et le conducteur pendant le processus de dénudage.

- Stockage pratique et sûr : Les outils sont facilement accessibles dans un tiroir sous l’entrée du câble, et les câbles finis peuvent être stockés en toute sécurité dans un tiroir en acier.

- Efficacité : L’entraînement par courroie fiable et rapide offre une vitesse d’alimentation de 9 m/s, contribuant ainsi à une haute productivité.

Specifications

| Wire cross sections | 0.13 – 6 mm² (AWG 26 – 10) |

| Wire draw-in speed | max. 9 m/s belt drive |

| Outer diameter of conductor | max. 5,1 mm |

| Length range | 60 – 65.000 mm / optional 30 – 60 mm (Wire length tolerance ± (0.2% + 1 mm)) |

| Full stripping | 0.1 – 18 mm / optional up to 29 mm |

| Half stripping | 15.5 mm / optional up to 35 mm |

| Crimp force | 1 – 22 kN |

| Process modules side 1/ 2 | 2 / 2 |

| Noise level | < 80 dB (without crimp tool) |

| Electrical connection | 3 × 208 – 480 V / 50 – 60 Hz / 5.6 k VA |

| Compressed air connection | 5 – 8 bar (73 – 116 psi.) |

| Air consumption Crimp / Crimp | < 7 m³/h |

| Air consumption Seal crimp /Seal crimp | < 11 m³/h |

| Weight (incl. 2 crimp modules) | 1.300 kg |

Downloads

La machine automatique de traitement des câbles Alpha 530 pour sertissage et scellement à double face répond aux normes de qualité élevées pour des sections de câbles de 0,13 à 6 mm². Il est possible de traiter des sections de câbles plus grandes sur demande, et Komax propose des tests de faisabilité pour pré-tester les câbles, en particulier les câbles très durs ou rigides qui peuvent ne pas être traités même s’ils respectent les spécifications.

Caractéristiques principales :

- Configuration flexible : L’Alpha 530 offre des capacités pour des applications spéciales et complexes telles que le double sertissage, l’insertion de bornes et de douilles pour fils, ainsi que le torsionnement et le vernissage des brins.

- Distances courtes entre les stations : La machine dispose de courtes distances entre les stations de sertissage, de câblage et de découpe, ce qui augmente la productivité.

- Zones de travail éclairées par LED : L’éclairage LED dans les zones de travail améliore la visibilité et la sécurité.

- Interface utilisateur intuitive : L’interface séquentielle et configurable individuellement améliore la facilité d’utilisation et accélère les réglages.

- Temps de réglage et de changement rapides : La machine offre des temps de changement rapides, augmentant l’efficacité même avec une production variable.

- Garantie de qualité : La surveillance de la force de sertissage (CFA+/CFA) est intégrée pour le contrôle de la qualité, et une surveillance de précision (ACD) en option peut être ajoutée pour détecter même le plus petit contact entre la lame et le conducteur pendant le processus de dénudage.

- Stockage pratique et sûr : Les outils sont facilement accessibles dans un tiroir sous l’entrée du câble, et les câbles finis peuvent être stockés en toute sécurité dans un tiroir en acier.

- Efficacité : L’entraînement par courroie fiable et rapide offre une vitesse d’alimentation de 9 m/s, contribuant ainsi à une haute productivité.

| Type | Crimp To Crimp |

|---|---|

| Max cross section (mm²) | 6 |