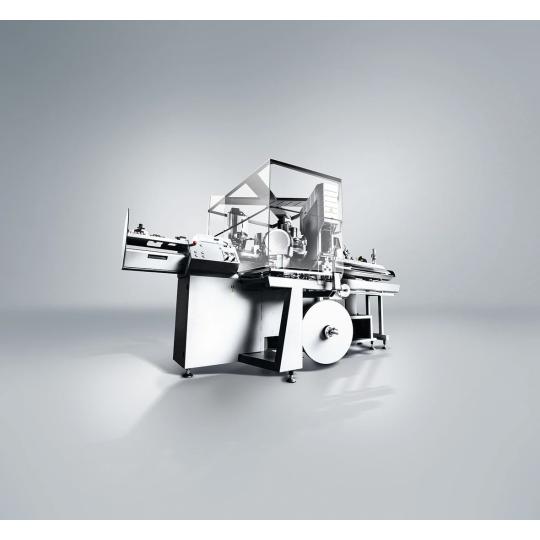

Komax - Fully Automatic Wire Processing Machine Alpha 530

KMX-0341000

Alpha 530: Volautomatische Kabelverwerkingsmachine voor Tweezijdig Krimpen en Verzegelen

Komax - Fully Automatic Wire Processing Machine Alpha 530

KMX-0341000

Alpha 530: Volautomatische Kabelverwerkingsmachine voor Tweezijdig Krimpen en Verzegelen

Hulp, installatie en/of training nodig?

Bel +32 (0)14 42 44 01 of neem contact met ons op

Beschrijving

De Alpha 530 volautomatische kabelverwerkingsmachine voor tweezijdig krimpen en verzegelen voldoet aan de hoge kwaliteitseisen voor kabeldoorsnedes van 0,13 – 6 mm². Het is mogelijk om grotere kabeldoorsneden te verwerken op aanvraag, en Komax biedt haalbaarheidstesten om kabels vooraf te testen, vooral voor zeer harde of stijve kabels die mogelijk niet worden verwerkt, hoewel ze binnen de specificaties vallen.

Belangrijkste kenmerken:

- Flexibele configuratie: De Alpha 530 biedt mogelijkheden voor speciale en complexe toepassingen, zoals dubbele krimp, huls- en adereindhulzeninvoer, en het draaien en vertinnen van strengen.

- Korte afstanden tussen stations: De machine heeft korte afstanden tussen krimp-, kabel- en snijstations, wat de productiviteit verhoogt.

- Verlichte werkzones: LED-verlichting in de werkzones zorgt voor een verbeterde zichtbaarheid en veiligheid.

- Intuïtieve gebruikersinterface: De sequentiële en individueel configureerbare interface verhoogt de gebruiksvriendelijkheid en de snelheid van de instelling.

- Korte instel- en omsteltijden: De machine biedt snelle omsteltijden, wat de efficiëntie verhoogt, zelfs bij variabele producties.

- Kwaliteitsgarantie: Krimpkrachtbewaking (CFA+/CFA) is ingebouwd voor kwaliteitscontrole, en optioneel kan incisiebewaking (ACD) worden toegevoegd om het kleinste contact tussen het blad en de geleider tijdens het stripproces te detecteren.

- Handige en veilige opslag: Het gereedschap is eenvoudig toegankelijk via een lade onder de kabelinvoer, en afgewerkte kabels kunnen veilig worden opgeborgen in een stalen lade.

- Efficiëntie: De betrouwbare en snelle riemaandrijving zorgt voor een invoersnelheid van 9m/s, wat bijdraagt aan een hoge productiviteit.

Specifications

| Wire cross sections | 0.13 – 6 mm² (AWG 26 – 10) |

| Wire draw-in speed | max. 9 m/s belt drive |

| Outer diameter of conductor | max. 5,1 mm |

| Length range | 60 – 65.000 mm / optional 30 – 60 mm (Wire length tolerance ± (0.2% + 1 mm)) |

| Full stripping | 0.1 – 18 mm / optional up to 29 mm |

| Half stripping | 15.5 mm / optional up to 35 mm |

| Crimp force | 1 – 22 kN |

| Process modules side 1/ 2 | 2 / 2 |

| Noise level | < 80 dB (without crimp tool) |

| Electrical connection | 3 × 208 – 480 V / 50 – 60 Hz / 5.6 k VA |

| Compressed air connection | 5 – 8 bar (73 – 116 psi.) |

| Air consumption Crimp / Crimp | < 7 m³/h |

| Air consumption Seal crimp /Seal crimp | < 11 m³/h |

| Weight (incl. 2 crimp modules) | 1.300 kg |

De Alpha 530 volautomatische kabelverwerkingsmachine voor tweezijdig krimpen en verzegelen voldoet aan de hoge kwaliteitseisen voor kabeldoorsnedes van 0,13 – 6 mm². Het is mogelijk om grotere kabeldoorsneden te verwerken op aanvraag, en Komax biedt haalbaarheidstesten om kabels vooraf te testen, vooral voor zeer harde of stijve kabels die mogelijk niet worden verwerkt, hoewel ze binnen de specificaties vallen.

Belangrijkste kenmerken:

- Flexibele configuratie: De Alpha 530 biedt mogelijkheden voor speciale en complexe toepassingen, zoals dubbele krimp, huls- en adereindhulzeninvoer, en het draaien en vertinnen van strengen.

- Korte afstanden tussen stations: De machine heeft korte afstanden tussen krimp-, kabel- en snijstations, wat de productiviteit verhoogt.

- Verlichte werkzones: LED-verlichting in de werkzones zorgt voor een verbeterde zichtbaarheid en veiligheid.

- Intuïtieve gebruikersinterface: De sequentiële en individueel configureerbare interface verhoogt de gebruiksvriendelijkheid en de snelheid van de instelling.

- Korte instel- en omsteltijden: De machine biedt snelle omsteltijden, wat de efficiëntie verhoogt, zelfs bij variabele producties.

- Kwaliteitsgarantie: Krimpkrachtbewaking (CFA+/CFA) is ingebouwd voor kwaliteitscontrole, en optioneel kan incisiebewaking (ACD) worden toegevoegd om het kleinste contact tussen het blad en de geleider tijdens het stripproces te detecteren.

- Handige en veilige opslag: Het gereedschap is eenvoudig toegankelijk via een lade onder de kabelinvoer, en afgewerkte kabels kunnen veilig worden opgeborgen in een stalen lade.

- Efficiëntie: De betrouwbare en snelle riemaandrijving zorgt voor een invoersnelheid van 9m/s, wat bijdraagt aan een hoge productiviteit.

| Type | Crimp To Crimp |

|---|---|

| Max cross section (mm²) | 6 |