Komax - Stripping Crimping Machine Delta 240

KMX-0410240

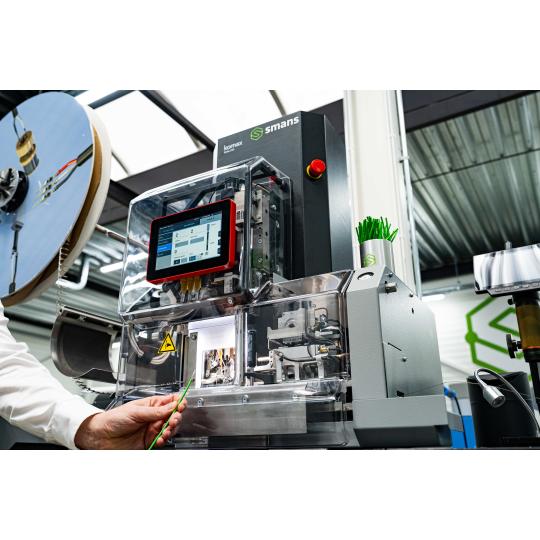

Delta 240: Semi-Automatic Crimping Machine with Crimp Force Monitoring and Automatic Crimp Height Adjustment

Komax - Stripping Crimping Machine Delta 240

KMX-0410240

Delta 240: Semi-Automatic Crimping Machine with Crimp Force Monitoring and Automatic Crimp Height Adjustment

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Delta 240 is a semi-automatic crimping and stripping machine with automatic crimp height adjustment and advanced crimp force monitoring. This machine is designed for high accuracy and process quality, ensuring excellent repeatability.

Key Features:

- Automatic Crimp Height Adjustment: Ensures consistent results without manual adjustments.

- CFA/CFA+ Crimp Force Monitoring: Reliably detects missing strands, incorrect cables, or insulation during the crimping process, ensuring quality.

- Precise Mechanics: Ensures high repeatability and reliable process quality.

- User-Friendly Interface: The graphical user interface enables intuitive operation, with context-sensitive help, language selection, and user rights.

- Minimal Operator Input: Thanks to programming, settings are reproducible, minimizing operator input.

- Increased Storage Capacity: The storage capacity has been expanded to 5,000 items.

- Optional Extensions: The Delta 240 can be equipped with a bad-contact cutter, extraction unit, and sequencing function for added functionality.

QCENTER SOFTWARE:

- Integration of Measuring Devices: The QCenter software integrates the crimp height and pull-out force measurement devices into the production process and ensures that production starts only when the target and actual values match.

- Preventing Production Errors: Manual data entry is no longer necessary, and production starts only when measurement values fall within the required tolerances.

- Optional Barcode Integration: A barcode scanner can be optionally integrated to use crimp height and pull-out force measuring devices such as Komax 341 or Q1210 on up to 20 crimpers.

- Real-Time Data Transfer to MES: Measurement data can be transmitted in real-time to an MES (Manufacturing Execution System) via the MIKO interface for storage and evaluation.

- Automatic Report Generation: Komax Print automatically generates a measurement report during production release and stores it locally.

Specifications

| Cross-section range | 0.03 – 6.6 mm² (AWG 32 – 9) |

| Storage | 5000 articles, 1000 wires, 500 terminals |

| Max. crimp force | 20 kN |

| Stroke | 10 - 40 mm |

| Shut height | standard 135.8 mm / on request 118.3 - 174.8 mm |

| Stroke repeat accuracy | 0.006 mm |

| Crimp height adjustment | automatic, programmable + 0.2 mm ... - 0.8 mm |

| Split cycle for closed terminals | 1 - 20 mm |

| Strip length | 0.1 - 13 mm |

| Cycle time | crimp < 0.8 s, strip + crimp < 1.8 s |

| Electrical connection | 1 × 230 VAC, 50/60 Hz, 180 – 260 V, 1 × 115 VAC, 60 Hz, 92-130 V, 2000 VA |

| Compressed-air connection | 4 – 6 bar |

| Dimensions (WxHxD) | 700 x 750 x 500 mm |

| Weight | approx. 110 kg |

The Delta 240 is a semi-automatic crimping and stripping machine with automatic crimp height adjustment and advanced crimp force monitoring. This machine is designed for high accuracy and process quality, ensuring excellent repeatability.

Key Features:

- Automatic Crimp Height Adjustment: Ensures consistent results without manual adjustments.

- CFA/CFA+ Crimp Force Monitoring: Reliably detects missing strands, incorrect cables, or insulation during the crimping process, ensuring quality.

- Precise Mechanics: Ensures high repeatability and reliable process quality.

- User-Friendly Interface: The graphical user interface enables intuitive operation, with context-sensitive help, language selection, and user rights.

- Minimal Operator Input: Thanks to programming, settings are reproducible, minimizing operator input.

- Increased Storage Capacity: The storage capacity has been expanded to 5,000 items.

- Optional Extensions: The Delta 240 can be equipped with a bad-contact cutter, extraction unit, and sequencing function for added functionality.

QCENTER SOFTWARE:

- Integration of Measuring Devices: The QCenter software integrates the crimp height and pull-out force measurement devices into the production process and ensures that production starts only when the target and actual values match.

- Preventing Production Errors: Manual data entry is no longer necessary, and production starts only when measurement values fall within the required tolerances.

- Optional Barcode Integration: A barcode scanner can be optionally integrated to use crimp height and pull-out force measuring devices such as Komax 341 or Q1210 on up to 20 crimpers.

- Real-Time Data Transfer to MES: Measurement data can be transmitted in real-time to an MES (Manufacturing Execution System) via the MIKO interface for storage and evaluation.

- Automatic Report Generation: Komax Print automatically generates a measurement report during production release and stores it locally.

| Type | Applicator Based Crimping |

|---|---|

| Max cross section (mm²) | 4 |