Resultaat 97–144 van de 192 resultaten wordt getoond

-

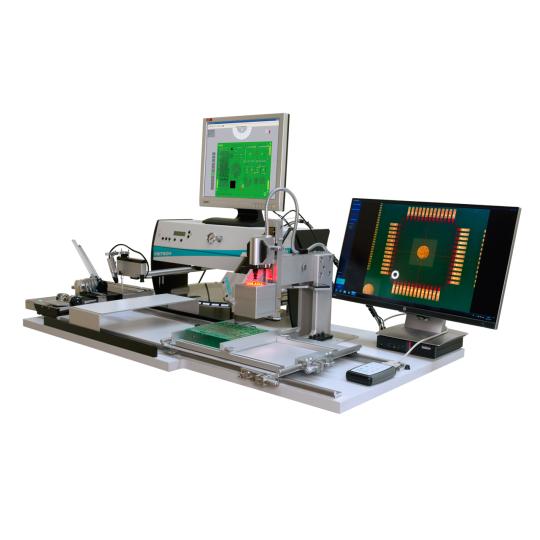

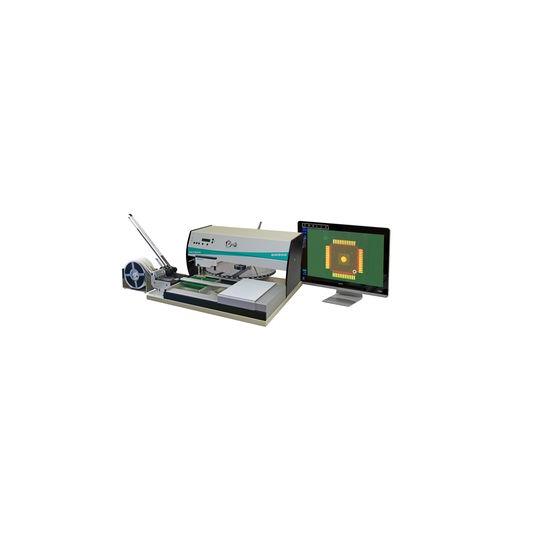

Fritsch – Batch Solder System

FRITSCH combines easy handling with low costs in the batch solder system. The user-friendly surface enables the individual programming to reduce setup-times to a mnimum. It doesn't matter wether prototyping or serial production: The batch systems are the perfect solution for daily work. -

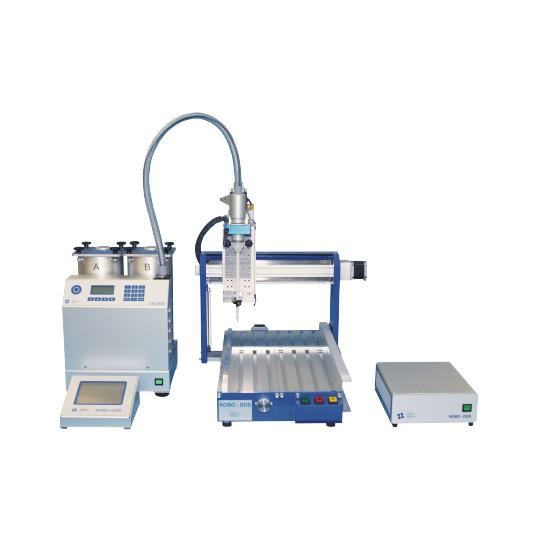

Giebler – THERMO-DOS

THERMO-DOS is een aanvullend systeem voor de meng- en doseringsmachines 2-K-DOS en 2-K-MiniDOS. Deze machine warmt de gietmassa's op. Op deze manier kunnen zeer viskeuze massa's minder viskeus worden gemaakt, zodat ze kunnen worden verwerkt in de machines en in de smalle spleten kunnen worden gegoten die worden gebruikt om gietproducten te maken. -

Kolb Cleaning Technology – Aqube LH721

AQUBE® LH7 is a fully automatic XL high volume new generation PCB fine cleaning system - except AQUBE® 9 types there are no PCB cleaning batch systems with a comparably large chamber size available worldwide - with a capacity of up to 540 (8.6 m²) eurocards and a relative cleaning time of 10 seconds per card.