Tools cleaning in electronics production

Maintenance and tools cleaning is an important task in electronics production. It is not only about ensuring reproducible production quality, but also about maintaining the value of the machinery. With the kolb maintenance cleaning systems and detergents such tasks can be performed perfectly. Sometimes, however, there are e.g. machine parts that cannot be cleaned easily. Or can they?

The challenge

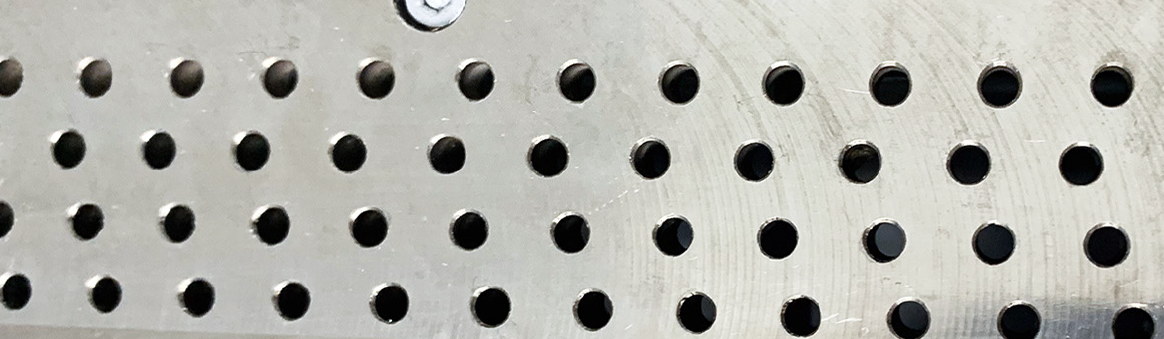

A classic example of such “uncleanable” elements are longer used pump parts from wave soldering systems. After extended use their function is no longer optimal because in particular the geometry of the solder nozzles in the distributor plate is contaminated with heavily burned-in soldering aids / oxides and soot. In addition, the mobility of pump gears and other moving parts suffers. If the contamination has reached a certain level, the pump plates have to be removed laboriously and mechanically cleaned or in many cases completely replaced in order to keep the soldering process stable.

With the right detergent, a pump unit can simply be machine-cleaned so that it can be reused trouble-free.

Essential: The detergent

The solder pump was cleaned with the special cleaner kolb StoveEx in a fully automatic kolb AF20 maintenance cleaning system with AirFlow air-in-immersion technology. The system is generally suitable for condensate filters, solder frames, carriers and small parts and also automatically performs the rinsing with water necessary for solder pump cleaning.

The StoveEx intensive cleaner is an extra strong alkaline concentrate specially formulated to remove persistent and stoved contaminations from solder nozzles, condensate traps, filter plates, coolers and cyclones. It can be used in immersion as well in ultrasonic systems.

source: kolb Cleaning Technology GmbH