Komax - Cut and Strip machine Kappa 350

KMX-0069000

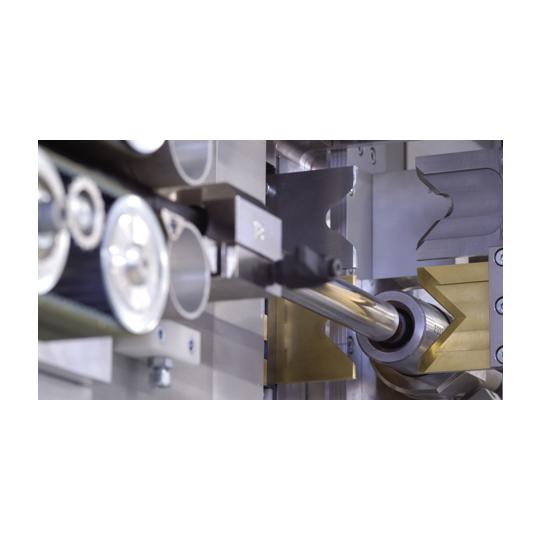

The Kappa 350 cutting and stripping machine processes round conductors up to 120 mm² and a maximum outer diameter of 35 mm in high quality thanks to sophisticated sensors.

Komax - Cut and Strip machine Kappa 350

KMX-0069000

The Kappa 350 cutting and stripping machine processes round conductors up to 120 mm² and a maximum outer diameter of 35 mm in high quality thanks to sophisticated sensors.

Need assistance, installation and/or training?

Call +32 (0)14 42 44 01 or contact us

Description

Kappa machines can process many conductors outside the specified cross-section range. However, certain extremely hard, stiff cables may not be processed, even if they fall within the specified range. If in doubt, we are happy to provide samples for your cables.

The Kappa 350 is a powerhouse: The cutting and stripping machine is highly cost-effective thanks to the strong belt drive or optional roller drive, with a cable feed speed of 4.8 m/s, accurate repeatability, and the cutting head with two blade positions. Innovative sensors assist with setup and take over quality control during use, minimizing cutting losses.

Key Features:

- High cable feed speed: 4.8 m/s for fast processing.

- Accurate repeatability: Ensures consistent results.

- Two blade positions: For flexible processing.

- Innovative sensors: For quality control and minimal cutting losses.

- Standardized connections: Easy integration of additional modules such as cable feeder systems, printers, active trays, and more.

TopWin software:

- Complete bill of materials and sequences: Generate sets with multiple cables or a cable harness.

- Cable labeling and network connection: Label cables, connect to the company network, and print waybills.

Specifications

| Wire cross-section, stranded wires | 2.5 – 120 mm² / AWG 14 – 5/0 (*) |

| Max. outer diameter | 35 mm |

| Length accuracy | Repeat accuracy (± (0.2 % + 1 mm)) |

| Wire length rang | e 1 – 800.000 mm |

| Max. wire transport speed | 4.8 m/s |

| Noise level | < 70 dBA |

| Drive system | Belt or roller drive |

| Electrical connection | 110/230 VAC ±10% - 50/60 Hz - 1.2 kVA |

| Dimensions (W × H × D) | 1.090 × 1.425 × 890 mm |

| Weight | approx. 270 kg |

Kappa machines can process many conductors outside the specified cross-section range. However, certain extremely hard, stiff cables may not be processed, even if they fall within the specified range. If in doubt, we are happy to provide samples for your cables.

The Kappa 350 is a powerhouse: The cutting and stripping machine is highly cost-effective thanks to the strong belt drive or optional roller drive, with a cable feed speed of 4.8 m/s, accurate repeatability, and the cutting head with two blade positions. Innovative sensors assist with setup and take over quality control during use, minimizing cutting losses.

Key Features:

- High cable feed speed: 4.8 m/s for fast processing.

- Accurate repeatability: Ensures consistent results.

- Two blade positions: For flexible processing.

- Innovative sensors: For quality control and minimal cutting losses.

- Standardized connections: Easy integration of additional modules such as cable feeder systems, printers, active trays, and more.

TopWin software:

- Complete bill of materials and sequences: Generate sets with multiple cables or a cable harness.

- Cable labeling and network connection: Label cables, connect to the company network, and print waybills.

| Type | Cut & Strip |

|---|---|

| Max cross section (mm²) | 120 |