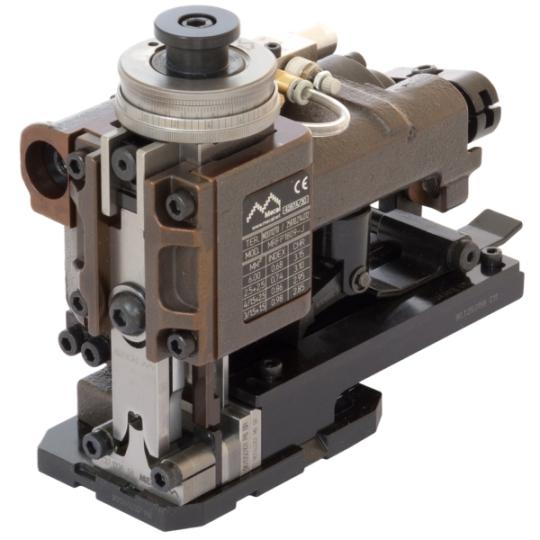

Mecal - Restyling Pneumatic Applicator

CS-fd916882

The Restyling Pneumatic Applicator

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Restyling pneumatic applicator is a mini-applicator for coupled terminals, with a thickness of < 1.2 mm, clamp distance > 27 mm (if the distance is smaller than 27 mm, a version with a pneumatic feeding system can be supplied upon request), and cable cross-section between 0 and 10 mm².

Key Features:

- Pneumatic side-feed system: Rolls coupled terminals from left to right on a reel.

- Continuous or four-pad regulating head: Available as an option.

- Non-resettable 7-digit cycle counter.

- Mounting compatibility: Can be mounted on any crimp press with a crimp height of 135.8 mm ± 0.02 mm (measured from the base plate of the mini-applicator to the T-joint of the press at the lower dead point).

- Versatile use: Can be used manually (for bench presses) or automatically (for cutting and stripping machines).

- Complete technical documentation: Includes all necessary information for safe operation and proper maintenance.

- Capacity study upon request: Includes a photo of a cross-sectioned crimped terminal.

Restyling Family Improvements:

- Replaceable anvil: The anvil can be replaced without removing the applicator from the press. The anvil is made of two parts, cable and insulation, allowing the worn part to be replaced only.

- Thicker base plate: The mini-applicator’s base plate is thicker for increased sturdiness.

- Easier crimper replacement: The body of the mini-applicator allows crimpers to be replaced without removing the ram or the applicator from the press.

- User-friendly pitch adjustment system: Terminal centering on the anvil is now even easier and is clearly illustrated in the detailed technical documentation.

- Produced under ISO 9001 certified quality management system (TÜV).

Specifications

| Crimping height | 135,8 mm |

| Stroke | 40 / 30 mm |

| Terminal pitch | > 27 mm |

| Max. stroke | 35 mm |

| Terminal thickness | < 1,2 mm |

| Wire section | max 10 mm² |

| Feeding system | air pressure 5/6 bar |

| Weight | 4,1 kg |

| Dimensions (WxHxD) | 140 x 145 x 105 mm |

| Options | Continuous regulation head, 0,01 mm resolution, 2,7 mm range |

The Restyling pneumatic applicator is a mini-applicator for coupled terminals, with a thickness of < 1.2 mm, clamp distance > 27 mm (if the distance is smaller than 27 mm, a version with a pneumatic feeding system can be supplied upon request), and cable cross-section between 0 and 10 mm².

Key Features:

- Pneumatic side-feed system: Rolls coupled terminals from left to right on a reel.

- Continuous or four-pad regulating head: Available as an option.

- Non-resettable 7-digit cycle counter.

- Mounting compatibility: Can be mounted on any crimp press with a crimp height of 135.8 mm ± 0.02 mm (measured from the base plate of the mini-applicator to the T-joint of the press at the lower dead point).

- Versatile use: Can be used manually (for bench presses) or automatically (for cutting and stripping machines).

- Complete technical documentation: Includes all necessary information for safe operation and proper maintenance.

- Capacity study upon request: Includes a photo of a cross-sectioned crimped terminal.

Restyling Family Improvements:

- Replaceable anvil: The anvil can be replaced without removing the applicator from the press. The anvil is made of two parts, cable and insulation, allowing the worn part to be replaced only.

- Thicker base plate: The mini-applicator’s base plate is thicker for increased sturdiness.

- Easier crimper replacement: The body of the mini-applicator allows crimpers to be replaced without removing the ram or the applicator from the press.

- User-friendly pitch adjustment system: Terminal centering on the anvil is now even easier and is clearly illustrated in the detailed technical documentation.

- Produced under ISO 9001 certified quality management system (TÜV).

| Type | Applicator |

|---|