Ulmer - Hose Cutting Machine SSM60 Touch

ULM-SSM60T

The hose cutting machine SSM60 T

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

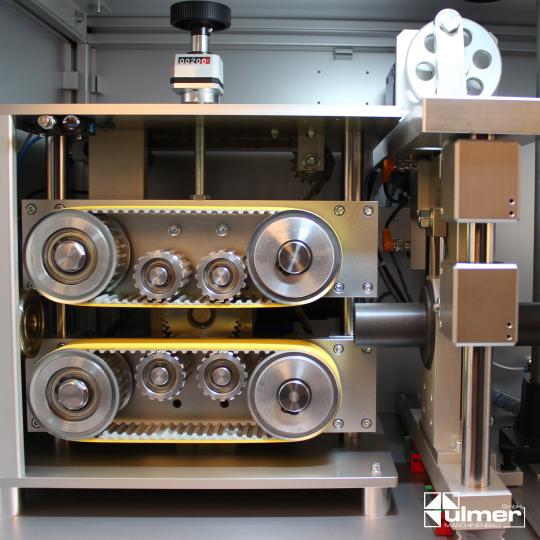

The SSM60 T hose cutting machine is designed for cutting closed and corrugated tubes, PVC, rubber hoses, and other types of hoses with an outer diameter of up to 60 mm. Thanks to the guillotine cutting process, with the blade positioned at a 45° angle, the machine ensures a precise cutting angle and excellent cutting quality.

Key Features:

- Suitable for various materials: Cuts closed and corrugated tubes, PVC, rubber hoses, and other types of hoses up to 60 mm O.D.

- Guillotine cut: Blade positioned at a 45° angle for precise cutting and high-quality cuts.

- Modern touchscreen control: Easy machine setup for new production processes or the use of existing production schedules.

- Powerful feed process: Material is accurately positioned and cut once the desired length is reached.

The SSM60 T provides a flexible and efficient solution for hose cutting, focusing on precision and ease of use.

Specifications

| Drive motor | servo |

| Length input | 0.1 mm steps |

| Max. feed rate | 1.2 m/s |

| Upper belt lift | pneumatically |

| Cutting head | pneumatically operated, optional electrically |

| Control panel | touch screen |

| Throughput diameter | up to 60 mm |

| Electrical supply | 230 V / 50 - 60 Hz |

| Compressed air supply | 6 bar |

| Dimensions (W x H x D) | 910 x 720 x 830 mm |

| Weight | 135 kg |

The SSM60 T hose cutting machine is designed for cutting closed and corrugated tubes, PVC, rubber hoses, and other types of hoses with an outer diameter of up to 60 mm. Thanks to the guillotine cutting process, with the blade positioned at a 45° angle, the machine ensures a precise cutting angle and excellent cutting quality.

Key Features:

- Suitable for various materials: Cuts closed and corrugated tubes, PVC, rubber hoses, and other types of hoses up to 60 mm O.D.

- Guillotine cut: Blade positioned at a 45° angle for precise cutting and high-quality cuts.

- Modern touchscreen control: Easy machine setup for new production processes or the use of existing production schedules.

- Powerful feed process: Material is accurately positioned and cut once the desired length is reached.

The SSM60 T provides a flexible and efficient solution for hose cutting, focusing on precision and ease of use.

| Type | Corrugated Tube Cutting |

|---|---|

| Max cross section (mm²) | 2.5 |

| Max outer diameter (mm) | 60 |