Z+F - Stripper-Crimper UNIC-GV

ZOL-V10AG000182

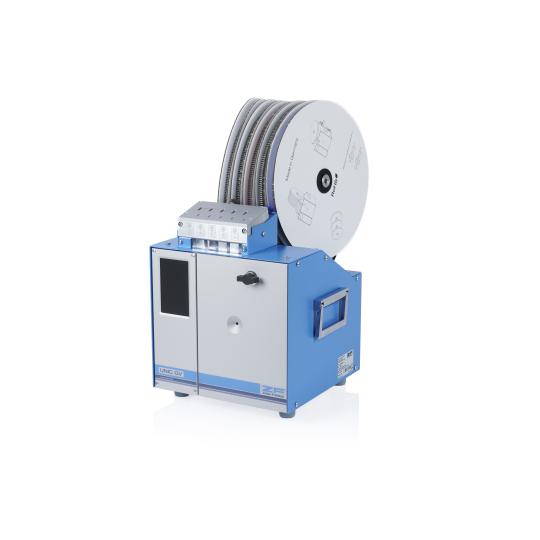

UNIC-GV: Electro-pneumatic Table Stripping and Crimping Machine

Z+F - Stripper-Crimper UNIC-GV

ZOL-V10AG000182

UNIC-GV: Electro-pneumatic Table Stripping and Crimping Machine

€12.598,36 / STK - In stock (1)

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The UNIC-GV is an electro-pneumatic table stripping and crimping machine that processes up to five reels of terminals with different cross-sections. Terminals ranging from 0.5 mm² to 2.5 mm² (AWG 20 – 14) with crimp lengths of 8 mm or 10 mm can be processed without downtime. The user simply selects the desired cross-section via a touchscreen. Terminals for multi-standard conductors can also be processed.

Key Features:

- Integrated process monitoring: Ensures continuous control during terminal processing.

- New 5″ graphical display: From the latest generation of Z+F machines for ease of use.

- Optimized terminal feed: Thanks to the improved terminal holder system for more efficient processing.

Specifications

| Crimping range | 0.5 - 2.5 mm² (AWG 20 - 14) |

| Crimping length | 8 /10 mm |

| Infeed length | 27 mm |

| Approx. cycle time | 2 seconds |

| Power supply | 100 V, 50 Hz | 240 V, 60 Hz |

| Air pressure | 5,5 bar |

| Dimensions (W x D x H) | 335 x 485 x 565 mm |

| Weight | 22 kg |

The UNIC-GV is an electro-pneumatic table stripping and crimping machine that processes up to five reels of terminals with different cross-sections. Terminals ranging from 0.5 mm² to 2.5 mm² (AWG 20 – 14) with crimp lengths of 8 mm or 10 mm can be processed without downtime. The user simply selects the desired cross-section via a touchscreen. Terminals for multi-standard conductors can also be processed.

Key Features:

- Integrated process monitoring: Ensures continuous control during terminal processing.

- New 5″ graphical display: From the latest generation of Z+F machines for ease of use.

- Optimized terminal feed: Thanks to the improved terminal holder system for more efficient processing.

| Type | Ferrule Processing |

|---|---|

| Max cross section (mm²) | 2.5 |