Schleuniger - CoaxCenter 6000

SCHLEUN-200000000140

Fully Automated Processing of Coax and Micro-Coax Cables

Schleuniger - CoaxCenter 6000

SCHLEUN-200000000140

Fully Automated Processing of Coax and Micro-Coax Cables

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

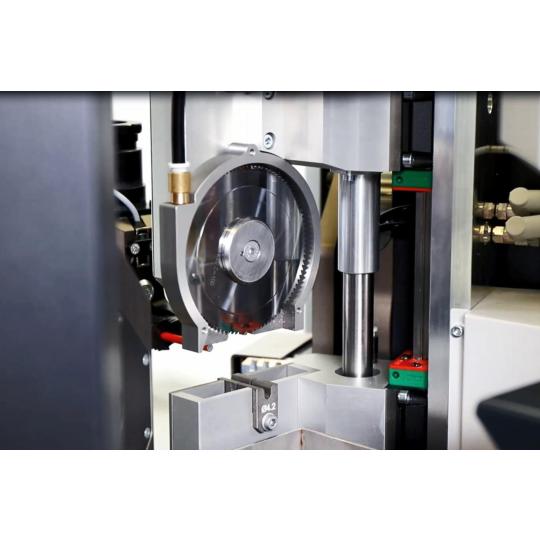

The CoaxCenter 6000 is the world’s first machine capable of fully automating and processing both micro-coax and coaxial cables as well as single-core wires with high precision. This machine aligns with the latest trends in automation, miniaturization, and the technologies of communications and mobility.

Key Features:

- Versatile applications: Suitable for processing micro-coax and coaxial cables as well as single-core wires, ideal for automation, miniaturization, ICT, and mobility technologies.

- Modular platform: The machine platform can be equipped with up to six processing stations, based on the customer’s needs.

- Efficient stripping: Uses the RotaryUnit 6000 or V-shaped blades with multiple blades for stripping, ensuring the cable is positioned optimally without being damaged by clamping pressure.

- Powerful suction system: Stripped cable parts are efficiently extracted.

- Position control: The cable end is held by a single gripper, ensuring its exact position is maintained and fed precisely to the processing stations.

- Quality monitoring: The QCam 360 camera system inspects each process step, ensuring correct positioning of crimp connections and detecting cuts or wire waste.

- Unique processing modules: Includes a centrally closing crimping press for small crimp applications and a fully programmable chamfer station for solid wire inner conductors.

- External station integration: The open machine concept allows for the integration of processing stations from other suppliers into the platform.

- Short changeover times: The machine is easy to set up, making it ideal for highly productive shift operations.

- High performance: Simultaneous processing of both cable ends with high speed and precision.

Specifications

| Processing Stations | Up to 6 stations |

| Conductor Cross Section | 0,005 mm² – 2.5 mm² * (40 AWG - 14 AWG) |

| Strip Length | Side 1: 0.1 mm (0.004“) - 58 mm (2.28") Side 2: 0.1 mm (0.004“) - 38 mm (1.49") |

Downloads

The CoaxCenter 6000 is the world’s first machine capable of fully automating and processing both micro-coax and coaxial cables as well as single-core wires with high precision. This machine aligns with the latest trends in automation, miniaturization, and the technologies of communications and mobility.

Key Features:

- Versatile applications: Suitable for processing micro-coax and coaxial cables as well as single-core wires, ideal for automation, miniaturization, ICT, and mobility technologies.

- Modular platform: The machine platform can be equipped with up to six processing stations, based on the customer’s needs.

- Efficient stripping: Uses the RotaryUnit 6000 or V-shaped blades with multiple blades for stripping, ensuring the cable is positioned optimally without being damaged by clamping pressure.

- Powerful suction system: Stripped cable parts are efficiently extracted.

- Position control: The cable end is held by a single gripper, ensuring its exact position is maintained and fed precisely to the processing stations.

- Quality monitoring: The QCam 360 camera system inspects each process step, ensuring correct positioning of crimp connections and detecting cuts or wire waste.

- Unique processing modules: Includes a centrally closing crimping press for small crimp applications and a fully programmable chamfer station for solid wire inner conductors.

- External station integration: The open machine concept allows for the integration of processing stations from other suppliers into the platform.

- Short changeover times: The machine is easy to set up, making it ideal for highly productive shift operations.

- High performance: Simultaneous processing of both cable ends with high speed and precision.

| Type | Coax Processing |

|---|---|

| Max cross section (mm²) | |

| Max stripping length (mm) |