What is voiding and does the reflow profile affect it?

Voiding

A phenomenon that occurs in the reflow soldering process.

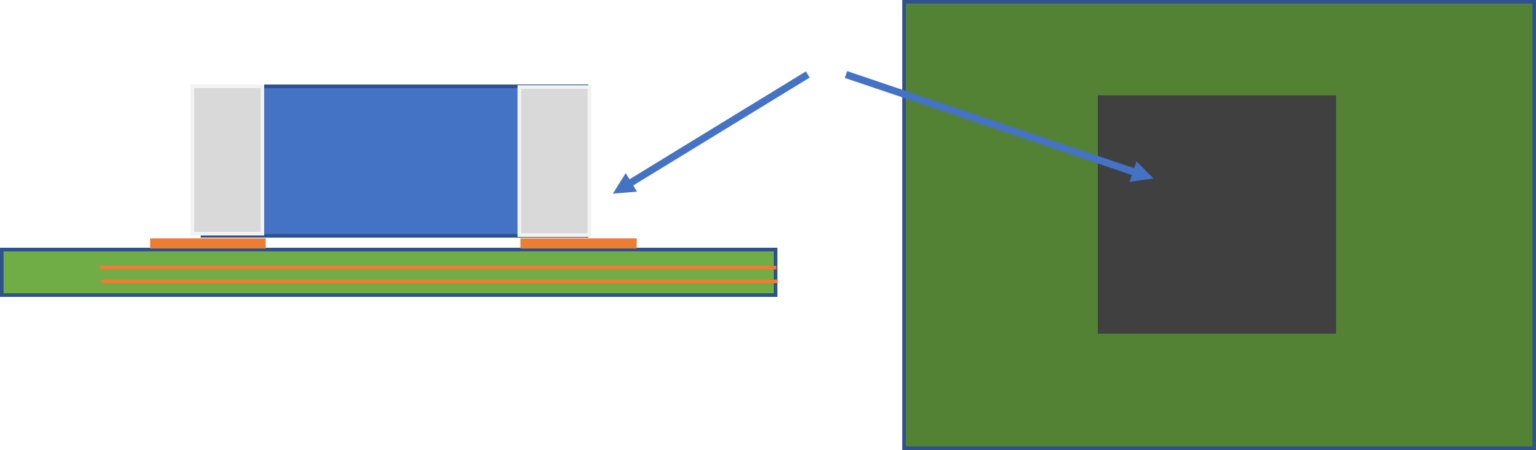

Bubbles (voids) begin to form in the flowed and solidified solder which make the solder joint hollow to a certain extent.

Cause of voiding

The cause of this phenomenon can be found in the outgassing of substances used in the various components, materials and PCBs. However, the main cause of these voids, which are in fact gas bubbles, is the solder paste used.

Solder paste consists of 2 main components, namely metal powder and flux. The flux contains resins and solvents, among other things, which all gas out when heated. When these gas bubbles have not left the liquid tin they become trapped in the solidified mass during the solidification of the solder. Especially in places under components it is extra difficult for the gases to escape because gases tend to move vertically.

How to reduce voiding

To reduce this problem, there are reflow ovens and vapour phase reflow systems on the market that generate a negative pressure or vacuum during the liquid phase, which ‘sucks’ the gas bubbles out.

The voiding can be avoided by adjusting the temperature profile. A zone of constant temperature is then created below the melting temperature of the solder. This allows the outgassing solder flux to escape without immediately becoming trapped in the liquid tin. Depending on the type of solder paste, this method has more or less effect.

Solder paste

Solder pastes can be specially designed and formulated to reduce outgassing. These solder pastes will, under the same conditions, show far fewer voids than standard solder pastes.

Interflux® DP 5505 solder paste is a low voiding solder paste. With GlobalPoint PTP reflow trackers and software, recording and adjusting temperature profiles becomes child’s play.

More info?

Leave your details via the contact form and we will contact you as soon as possible!