What are halogens doing in a flux and what danger do they pose?

Halogens in a flux

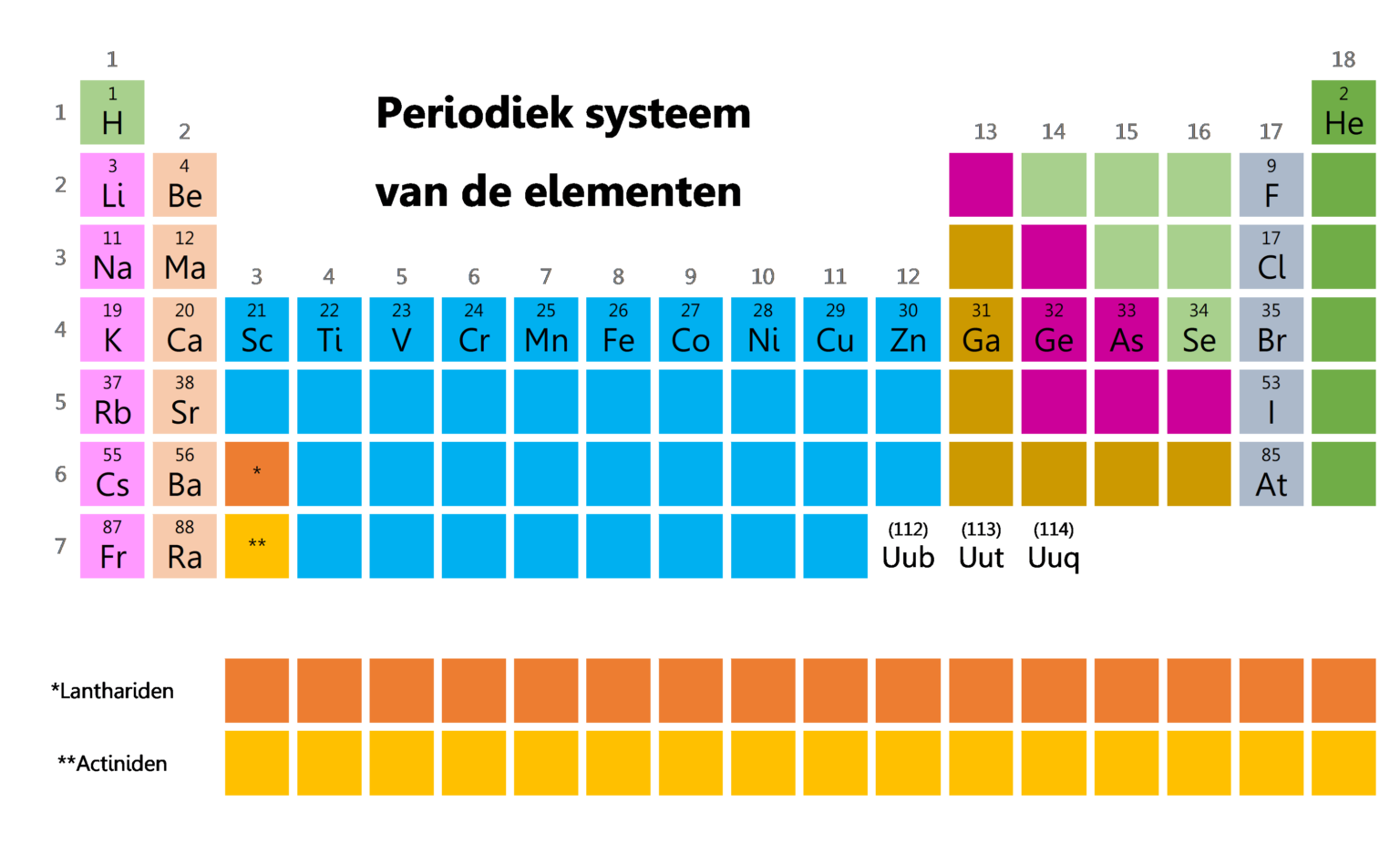

Halogens are chemical elements that have the property of reducing metals efficiently. In the process, metal salts are formed that are usually very soluble in water and also attract and retain moisture from the environment. Moisture and metal salts together create an electrically conductive medium. This significantly increases the chance of electromigration and corrosion on electronic circuits.

Consequences

Electromigration and corrosion often result in electric currents finding other paths to flow than the intended ones. This can have various consequences for the operation of an electronic circuit; malfunctioning, misinterpretation of data, component failure and even the burning out of entire systems.

The metal salt SnCl2 formed by Sn (tin) and Cl (halogen) is almost 100 times more soluble in water than the metal salt PbCl2 formed by lead and chlorine. This means that much more damage can be caused in a lead-free process than in a process containing lead if halogens are used.

How to prevent halogens in a flux

It is therefore necessary to always give preference to absolutely halogen-free soldering products. An IPC Class L0 product still allows a quantity of halogens of < 500 ppm according to the J-STD-004B standard.

Interflux® has a soldering range with ‘absolutely halogen free’ products including soldering wire, solder flux or solder paste.

More info?

Leave your details via the contact form and we will contact you as soon as possible!