How to avoid tombstoning during PCB assembly

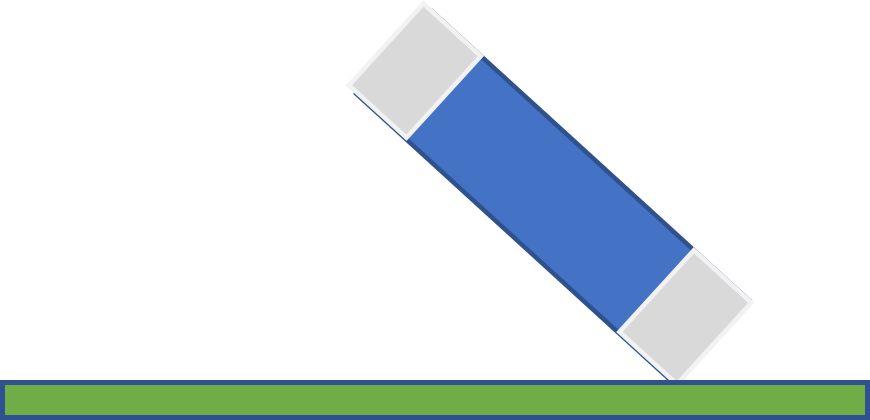

Tombstoning

A situation that occurs during the reflow soldering process, especially in a vapour phase or vapour phase reflow system.

It means that passive chip components such as resistors and condensers stand upright during soldering.

The cause of tombstoning

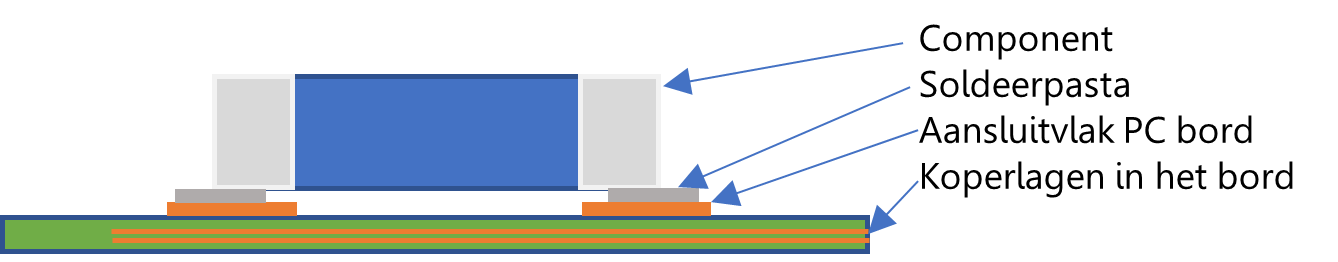

The cause of this problem is to be found in the accidental flow of solder paste on the two contact ends of the component. When one of the two ends goes into liquid phase in front of the other, the liquid solder paste pulls the component upright.

The cause of this problem is to be found in the accidental flow of solder paste on the two contact ends of the component. When one of the two ends goes into liquid phase in front of the other, the liquid solder paste pulls the component upright.

The uneven thermal loading of the connection surfaces of this component on the PCB is responsible for the uneven flow.

Methods of preventing tombstoning

There are a number of options to tackle this soldering defect. The most logical but also the most radical action is to redesign the copper layers in the PCB so that the thermal load on the soldering surfaces is equalised. This is a cumbersome task that requires access to the design files and specialised knowledge. In many cases this is not feasible for a subcontractor.

Another option is at the level of stencil design. This adjusts the shape and position of the paste that is pressed onto the connection surfaces of the PCB. This requires a new stencil, specialised knowledge and often some testing.

One option that has the least impact on the production process and does not require specialised knowledge from the user is to adjust the solder paste so that it does not suddenly flow at a certain point but does so gradually, making the flow even and simultaneous.

One option that has the least impact on the production process and does not require specialised knowledge from the user is to adjust the solder paste so that it does not suddenly flow at a certain point but does so gradually, making the flow even and simultaneous.

The Interflux IF 9057 ATL solder paste is a SAC305 – T4 paste with anti-tombstone function built in. It gives clear and minimal residue after soldering and is absolutely halogen free.

More info?

Leave your details via the contact form and we will contact you as soon as possible!

– Written by Bart van de Lisdonk