MPCS chooses flexibility in production with Komax Alpha 565

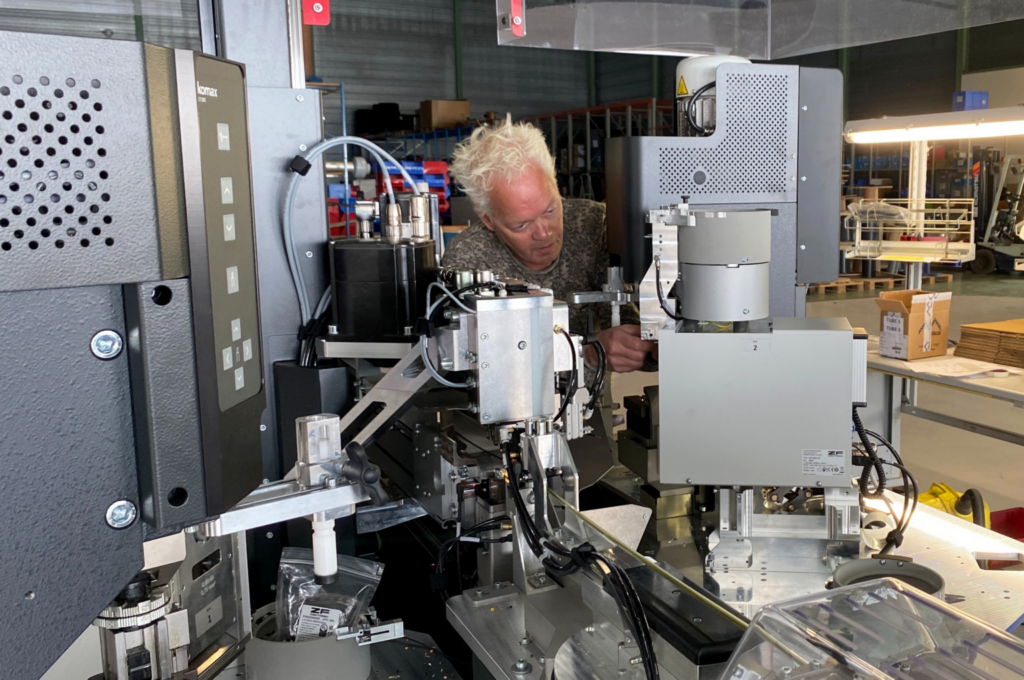

MPCS has been located in the beautiful city of Breda (NL) for several years now. They are the specialist in the design and implementation of wire harnesses, cable assembly, special cables, data cabling and spiral cables. A few months ago they bought a fully automatic wire processing machine from Komax, the Alpha 565, from Smans. We spoke to Ton Kers – managing director of MPCS.

MPCS stands for Multi Purpose Cable Solutions. They are pioneers in spiralising all kinds of cables, whether it is a simple telephone cord or a complex set of air hoses. To get and keep the spiral in the cable, they built a special heating oven which is still used daily.

Over the years, their portfolio has expanded considerably. They have specialised in, among other things, the design and production of cable trees, serial module construction and small or large series of cable assemblies. Their production is custom-made. Customers are mainly active in the automotive, defence, aviation, etc. industries. Sectors with high quality standards that MPCS always considers of paramount importance.

Wire harness produced by Komax Alpha 565

MPCS is happy with the automatic wire processing machine Alpha 565 from Komax.

Automatic wire production

The search for quality wire and components is currently the biggest challenge. “We have to move so fast these days that we are forced to produce everything in-house,” says Ton. “There is no time for outsourcing in China. A few years ago, we moved here because we needed more stock and production space to be able to automate.”

Purchase of fully automatic wire processing machine

Why did MPCS choose the Alpha 565 from Komax? “For the machine’s versatility and flexibility”, says Ton enthusiastically. “We used to make large investments in separate benchtop applicators. Now these applicators are integrated into the Alpha 565. With this machine we can adapt to future market changes.”

The Alpha 565 from Komax is an expandable wire processing machine with seven process modules. Not only can this machine crimp and seal wires on both sides, but thanks to the modules, special operations such as applying wire end ferrules, printing with inkjet or twisting / tinning can be perfectly integrated.

Komax is a very reliable brand,” adds Ton. There is remarkably little downtime with these machines. In the years that we work with them, I can count that on one hand. We have a good relationship with Smans as our partner in the BeNeLux. We are always on the same wavelength. The choice for them as a supplier was therefore an easy one.

Expansion possibilities of the Komax Alpha 565

Thanks to the Alpha 565, there is room for MPCS to expand. Now they use 4 modules to make wire badges. “We still mark our wires with a wrap label and/or shrink sleeve. In the future we want to switch to wire printing with inkjet.”

No matter how the market will change in the future, MPCS has the right machine to carry out their wire production in the most efficient and quality way as possible.