Pin-hole ratio: What is the influence on liquid tin and what ratio is ideal?

Pin-hole ratio

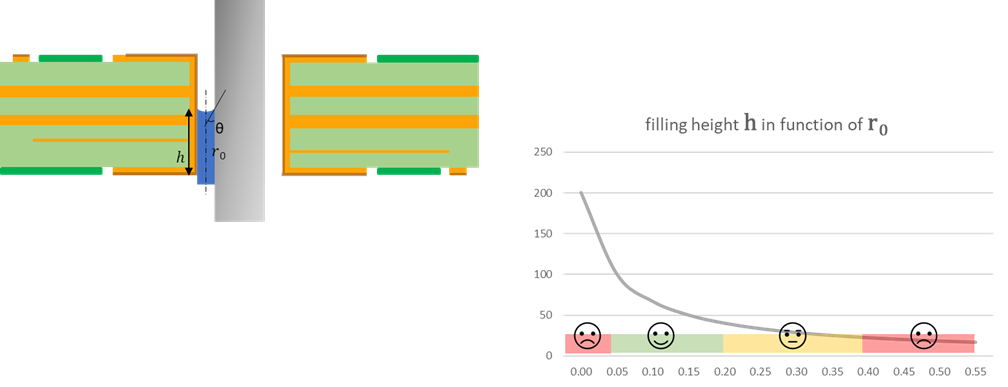

With through hole components, the connection pins go through a PCB. The space between a connecting pin and the hole in the PCB will determine the capillary effect. This effect ensures that the flux and liquid tin are ‘sucked’ up into the space between the pin and the hole.

A good pin to hole ratio is therefore one of the crucial parameters in the successful soldering of through hole components.

Control of the capillary effect

It is important that first the flux capillary is ‘sucked’ up into the hole so that the surfaces of the hole and the pin can be made oxide-free so that the soldering tin in turn can rise optimally.

To get the strongest capillary effect, the open area between the pin and hole must be between 150 µm and 350 µm.

The use of N2 has a positive influence on the capillary action and is particularly important in selective soldering. Also in wave soldering an N2 atmosphere has a favourable effect on the rising of the solder in the holes.

More info?

Leave your details via the contact form and we will contact you as soon as possible!