What are Lead-free, low melting point solder alloys?

The melting points of typical lead free solder alloys are situated in the 217 to 227°C range, depending the ratio of the main alloy’s metals; Sn, Ag and Cu. In comparison with the old tin-lead (SnPb) alloys these melting points of standard lead-free alloys are 40 to 50°C higher.

For a number of components and processes, a lower melting point lead-free alloy would be more desirable.

When the melting point is low, the process temperatures can also be lowered. This means components and products which before would be damaged by high temperatures, now can be processed with a lot more ease.

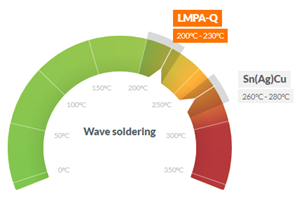

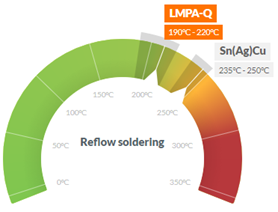

What does this mean in my different soldering processes?

LMPA-Q® is a lead-free, low melting solder alloy with a final melting point of 176°C. This allows temperatures to go down significantly in soldering processes.

For wave soldering typical solder bath settings for LMPA-Q® are around 230-250°C.

In reflow soldering peak temperatures of 190-215°C are the norm with LMPA-Q®.

For selective soldering, there is a dual option. A lower solder pot temperature of around 230°C or, a higher solder pot temperature as used with normal Lead-free alloys but with process speeds up to 5 times higher than current selective soldering speeds.

What are other benefits a low melting point alloys offers?

- Since the melting point is lower, the energy cost to keep LMPA-Q® liquid could be 20-25% lower.

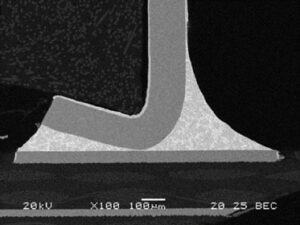

- Faster wetting and better through hole filling compared to standard Lead-free soldering alloys.

- Lower alloy cost. Since LMPA-Q does not contain any silver (Ag) the alloy cost could be up to 40% less.

- Low voiding in solder paste.