Stencil printing – the basis for flawless SMT production

Stencil printing is the essential first step in the SMT assembly process. During this process, solder paste or adhesive is applied to the printed circuit board (PCB) with extreme precision using a steel stencil. The quality of this print directly determines the reliability of solder joints and the functioning of electronic components. Even a small deviation in the paste print can later lead to costly production errors or malfunctions – which is why an accurate and repeatable stencil printing process is crucial for every modern electronics manufacturer.

From manual to fully automated

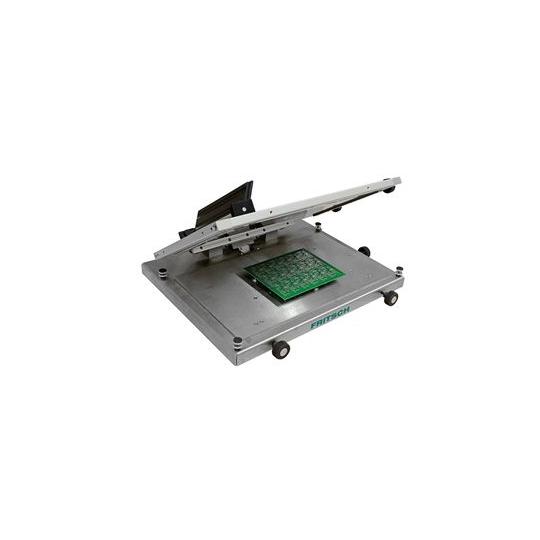

SMANS NV offers a complete range of stencil printers – from manual systems for prototyping and small series to fully automatic printers that integrate seamlessly into high-end production lines. Ersa machines, including the VERSAPRINT 2 series (ELITE, ELITE plus, PRO², and ULTRA³), combine speed, precision, and intelligent inspection technology for optimum process reliability.

With features such as automatic stencil cleaning, camera-controlled alignment, closed-loop process control, and 2D or 3D inspection, every print result is checked and optimized before assembly. This reduces the risk of defects, increases production efficiency, and ensures consistent quality in every print cycle.

Precision, speed, and reliability

Whether you need fine-pitch components, large PCB formats, or small series with frequent product changes, SMANS delivers stencil printing solutions that fit your production environment. The modern systems are distinguished by short changeover times, user-friendly operation, and maximum repeatability. Thanks to the optional integration of inspection and feedback systems, each process is monitored and adjusted step by step.

With over 50 years of experience, independent expertise, and a customer satisfaction rating of 9+, SMANS is the reliable partner for any company looking to optimize its SMT line with innovative and future-proof stencil printing technology.