Komax - Cut and Strip machine Kappa 340

KMX-0406001

The Kappa 340 handles the precise processing of uneven cable surfaces, battery, multicore, HV and sensor cables as well as hard, tough, thick and thin insulation (*).

Komax - Cut and Strip machine Kappa 340

KMX-0406001

The Kappa 340 handles the precise processing of uneven cable surfaces, battery, multicore, HV and sensor cables as well as hard, tough, thick and thin insulation (*).

Need assistance, installation and/or training?

Call +32 (0)14 42 44 01 or contact us

Description

Kappa machines can process many cables outside the specified cross-section range. It may not be possible to process extremely hard, stiff cables, even if they fall within the specified range. If in doubt, we are happy to provide samples for your cables.

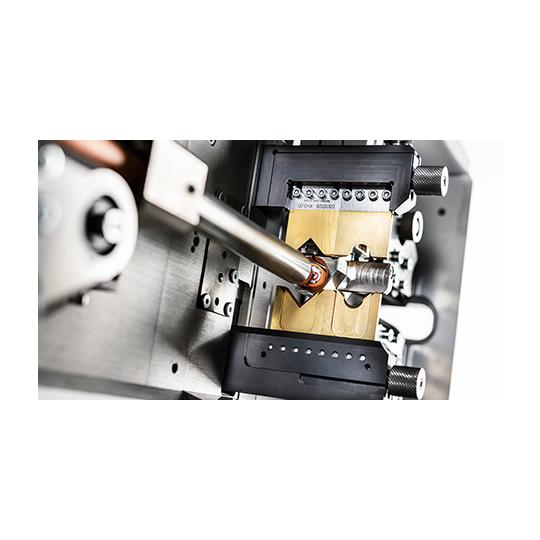

The Kappa 340 cutting and stripping machine is equipped for a wide range of applications, offering high performance. The machine features:

- Double cutting head: Processes cables from 0.22 to 70 mm² and ribbon cables up to 16 mm in width.

- Rotating cutting unit (optional): For quick changeover times and precise round cuts.

- Efficient cable processing: With rotating, cutting, and stripping knives and a belt drive with high torque and good grip, the Kappa 340 can efficiently process even difficult cables at speeds of up to 4 m/s.

- TopWin software: For generating bill of materials, sequences, and cable harnesses. It also allows for cable labeling, connecting to the company network, and printing waybills.

Options:

- Double head with shaping blade for precise processing

- Optional double head with separation unit

- Optional double head with V-blade and V-shaped blade

- Belt drive with high torque and long support surface

Specifications

| Wire cross-section, stranded wires | 0.22 – 70 mm² / AWG 24 – 2/0 (*) |

| Max. outer diameter | 16 mm |

| Length accuracy | Length tolerance (± (0.2 % + 1 mm)) |

| Flat wire processing | Optional 16mm |

| Wire length range (short mode possible) | 1 – 800.000 mm |

| Rotary incision | Standard programmable incision diameter on one or more wire layers |

| Max. wire transport speed | 4.0 m/s |

| Wire transport system | Multiple supported belt drive |

| Electrical connection | 110/230 VAC ±10% - 50/60 Hz - 650 VA |

| Dimensions (W × H × D) | 760 × 380 × 1.005 mm |

| Weight | 75 kg |

Kappa machines can process many cables outside the specified cross-section range. It may not be possible to process extremely hard, stiff cables, even if they fall within the specified range. If in doubt, we are happy to provide samples for your cables.

The Kappa 340 cutting and stripping machine is equipped for a wide range of applications, offering high performance. The machine features:

- Double cutting head: Processes cables from 0.22 to 70 mm² and ribbon cables up to 16 mm in width.

- Rotating cutting unit (optional): For quick changeover times and precise round cuts.

- Efficient cable processing: With rotating, cutting, and stripping knives and a belt drive with high torque and good grip, the Kappa 340 can efficiently process even difficult cables at speeds of up to 4 m/s.

- TopWin software: For generating bill of materials, sequences, and cable harnesses. It also allows for cable labeling, connecting to the company network, and printing waybills.

Options:

- Double head with shaping blade for precise processing

- Optional double head with separation unit

- Optional double head with V-blade and V-shaped blade

- Belt drive with high torque and long support surface

| Type | Cut & Strip |

|---|---|

| Max cross section (mm²) | 70 |