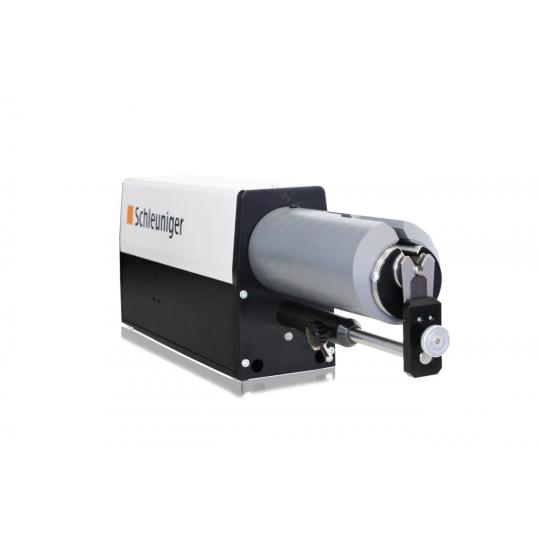

Schleuniger - Cutting Machine FiberOptic 7010

SCHLEUN-100000FO7010

Compact Kevlar stripping machine for fast and safe removal of reinforcement fibers from fiber optic cables.

Schleuniger - Cutting Machine FiberOptic 7010

SCHLEUN-100000FO7010

Compact Kevlar stripping machine for fast and safe removal of reinforcement fibers from fiber optic cables.

€9.863,94 / STK - In stock (1)

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Schleuniger FiberOptic 7010 is a compact, highly accurate Kevlar stripping machine specially designed for cutting and removing Kevlar reinforcements in fiber optic cables. Where Kevlar is difficult to process with conventional tools, the FiberOptic 7010’s patented system ensures fast, clean, and safe cutting without damaging the fiber structure of the cable.

The machine automatically sucks the Kevlar fibers into the cutting head with an integrated vacuum system and efficiently removes them via a microporous filter, preventing fibers from entering the working environment. Thanks to its pneumatically driven cutting stroke and adjustable cutting length, the FiberOptic 7010 is the ideal solution for professional fiber optic processing with consistent quality and high process reliability.

Specifications

| Compressed-air connection | 5-7 bar |

| Electrical connection | 100/115/230 VAC, 50/60 Hz, 1000 VA (vacuum system) |

| Max Strip Length | 30 mm |

| Min. Strip Length | 3 mm |

| Wire Outer Diameter | 4,5 mm |

Downloads

The Schleuniger FiberOptic 7010 is a compact, highly accurate Kevlar stripping machine specially designed for cutting and removing Kevlar reinforcements in fiber optic cables. Where Kevlar is difficult to process with conventional tools, the FiberOptic 7010’s patented system ensures fast, clean, and safe cutting without damaging the fiber structure of the cable.

The machine automatically sucks the Kevlar fibers into the cutting head with an integrated vacuum system and efficiently removes them via a microporous filter, preventing fibers from entering the working environment. Thanks to its pneumatically driven cutting stroke and adjustable cutting length, the FiberOptic 7010 is the ideal solution for professional fiber optic processing with consistent quality and high process reliability.

| Type | Fiber Stripping |

|---|---|

| Max outer diameter (mm) | |

| Max stripping length (mm) |