Komax - Data Wire Lambda 240

CS-3a226f82

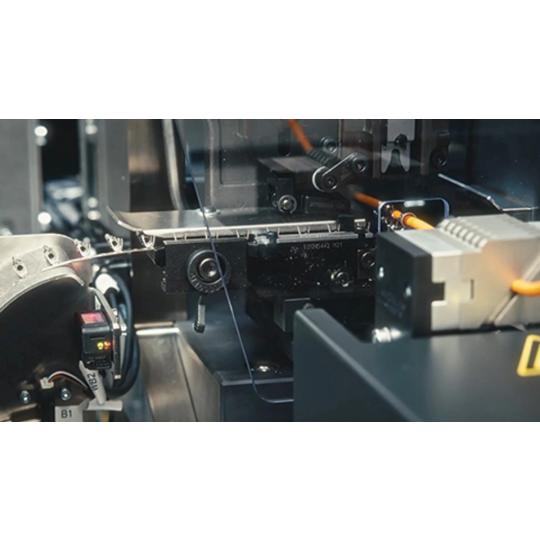

The Lambda 240: processing of high-voltage cables

Price on request

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Lambda 240 is designed for processing smaller quantities of different types of high-voltage cables. Thanks to quick changeover times, products can be easily swapped, ensuring flexibility.

Key Features:

- Quick changeover time: Allows for easy and fast product swaps.

- Flexible tool change: Suitable for various processing operations of high-voltage cables.

- Modular platform system (MPS): The machine layout can be individually designed with the required process modules.

- Space-saving design: Available in two sizes, the narrow design supports 2-3 process modules, while the wider version accommodates 2-5 process modules.

- Ideal for small production volumes: Perfect for volumes ranging from 250 to 600,000 cable ends per year.

- Traceability: Full traceability of materials and tools.

- Processing quality: Processes cable ends to the highest quality standards.

The Lambda 240 is designed for processing smaller quantities of different types of high-voltage cables. Thanks to quick changeover times, products can be easily swapped, ensuring flexibility.

Key Features:

- Quick changeover time: Allows for easy and fast product swaps.

- Flexible tool change: Suitable for various processing operations of high-voltage cables.

- Modular platform system (MPS): The machine layout can be individually designed with the required process modules.

- Space-saving design: Available in two sizes, the narrow design supports 2-3 process modules, while the wider version accommodates 2-5 process modules.

- Ideal for small production volumes: Perfect for volumes ranging from 250 to 600,000 cable ends per year.

- Traceability: Full traceability of materials and tools.

- Processing quality: Processes cable ends to the highest quality standards.

| Type | High Voltage |

|---|