Komax - Fully Automatic Wire Processing Machine Gamma 450

KMX-0373000

Compact Fully Automated Cable Processing Machine

Komax - Fully Automatic Wire Processing Machine Gamma 450

KMX-0373000

Compact Fully Automated Cable Processing Machine

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

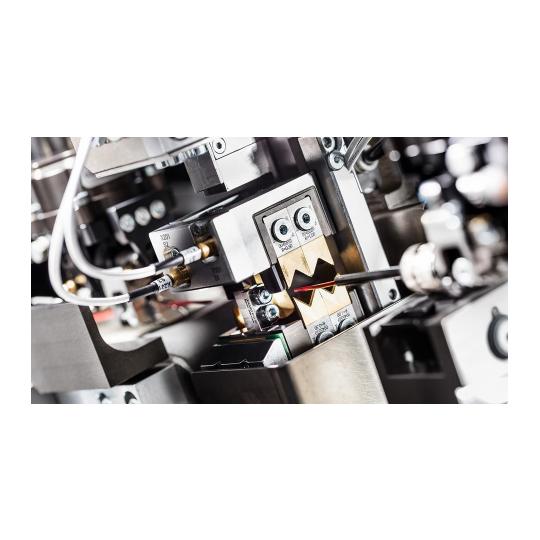

The Gamma 450 is a compact fully automated cable processing machine that performs crimping and sealing on both sides for cables with a cross-section of 0.13 – 4 mm². Despite its compact design, the machine delivers impressive performance. It offers seamless, fully integrated quality monitoring with CFA/CFA+, ACD, and Q1250, and can be customized with optional modules to meet high, future-oriented demands.

Key Features:

- Flexible configuration: The machine can be configured individually on four stations to meet specific process requirements.

- Automotive industry applications: The Gamma 450 is particularly suited for the automotive industry and its evolving demands for sustainable machines.

- Ergonomic design: The ergonomic design and logical workflows enhance economic efficiency and make the machine easy to operate.

- Quick-change system: Clamp spools and crimping tools can be replaced during operation with the quick-change system for STC tools and clamp spools.

- Fast setup and wire feed: No guiding elements are required for quick setup and wire feed.

- Optional extras: Stationary tools and quick-change systems for clamp spools can be added.

- Advanced cutting and quality monitoring: The dual cutting blade holder with dual head provides ACD precision monitoring, and optical quality control with the Q1250 ensures reliable quality monitoring.

- Easy operation: The module can be easily configured, increasing ease of use.

Specifications

| Wire cross-sections | 0.13 – 4 mm² (AWG 26 – AWG 12) (*) |

| Wire draw-in speed | max. 8m/s belt drive |

| Wire outer diameter | max. 3.9 mm |

| Length range | 60 – 65.000 mm (Repeat accuracy ± (0.2 % + 1 mm) - Deposit length > 8 m on request) / optional 33 – 60 mm |

| Full strip | 0.1 – 16.5 mm (*) / With optional double blade up to 35 mm |

| Partial strip | 0.1 – 16 mm (*) / With optional double blade up to 21 mm (S1) and 34.5 mm (S2) |

| Crimp force | 1 – 22 kN |

| Process modules | Side 1 and side 2: 2 stations |

| Noise level | < 75 dB (without crimp tool) |

| Electrical connection | 3 × 208 – 480 V; 50/60 Hz; 2.5 kVA or 3 × 400 V, 50/60 Hz, 2.5 kVA |

| Compressed-air connection | 5 – 8 bar |

| Recommended operating pressure | 6 ± 0.5 bar |

| Air consumption of crimp /crimp | < 6 m³/h |

| Air consumption of seal crimp / seal crimp | < 9 m³/h |

| Weight (incl. 2 crimp modules + 2 seal modules) | 920 kg |

Downloads

The Gamma 450 is a compact fully automated cable processing machine that performs crimping and sealing on both sides for cables with a cross-section of 0.13 – 4 mm². Despite its compact design, the machine delivers impressive performance. It offers seamless, fully integrated quality monitoring with CFA/CFA+, ACD, and Q1250, and can be customized with optional modules to meet high, future-oriented demands.

Key Features:

- Flexible configuration: The machine can be configured individually on four stations to meet specific process requirements.

- Automotive industry applications: The Gamma 450 is particularly suited for the automotive industry and its evolving demands for sustainable machines.

- Ergonomic design: The ergonomic design and logical workflows enhance economic efficiency and make the machine easy to operate.

- Quick-change system: Clamp spools and crimping tools can be replaced during operation with the quick-change system for STC tools and clamp spools.

- Fast setup and wire feed: No guiding elements are required for quick setup and wire feed.

- Optional extras: Stationary tools and quick-change systems for clamp spools can be added.

- Advanced cutting and quality monitoring: The dual cutting blade holder with dual head provides ACD precision monitoring, and optical quality control with the Q1250 ensures reliable quality monitoring.

- Easy operation: The module can be easily configured, increasing ease of use.

| Type | Crimp To Crimp |

|---|---|

| Max cross section (mm²) | 4 |