Komax - Test module Q1250

QT-d4596df0

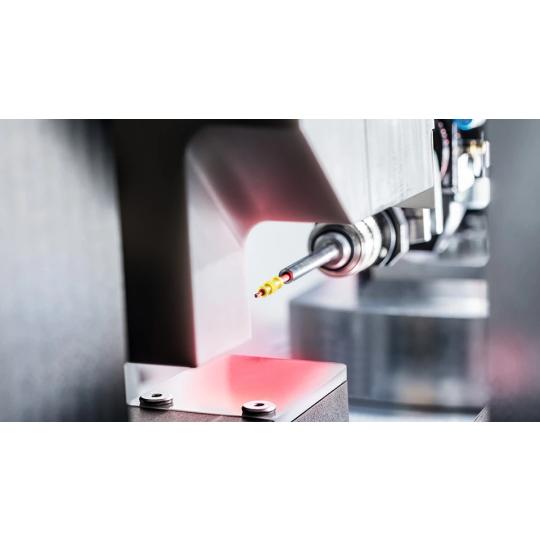

Q1250 Test Module: Scalable Quality Control for Stripping, Crimping, and Sealing

Komax - Test module Q1250

QT-d4596df0

Q1250 Test Module: Scalable Quality Control for Stripping, Crimping, and Sealing

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Q1250 is a modular and scalable testing solution designed to inspect stripping, crimping, and sealing processes. In its basic version, it offers fully automated verification of stripping success, sealing presence, and crimp integrity.

Flexible Scalability and Expandability

- Upgradeable from a basic monitoring tool to a high-end inspection system.

- Expandable with licenses and a dome light, adapting to evolving requirements.

- A single integrated tool enables comprehensive quality testing without major adjustments.

Smart and Efficient Quality Control

- Automatic parameter verification via an algorithm, independent of the operator.

- Eliminates manual visual inspections and reduces changeover times.

- Provides significant time savings while increasing productivity.

✔ Scalable digital wire-end detection ensures reliable and future-proof quality assurance.

Specifications

| Camera coverage | 24 x 16 mm |

| Strip length | max. 18 mm |

| Pixel resolution | 1024 x 768 pixels |

| Wire cross section | min. 0.13 mm² - max. 6 mm² |

| Wire criss section on request but with restrictions | > 6 mm² |

| Dimensions (L x W x H) | 90 x 290 x 524 mm |

| Weight | 3,4 kg |

Downloads

The Q1250 is a modular and scalable testing solution designed to inspect stripping, crimping, and sealing processes. In its basic version, it offers fully automated verification of stripping success, sealing presence, and crimp integrity.

Flexible Scalability and Expandability

- Upgradeable from a basic monitoring tool to a high-end inspection system.

- Expandable with licenses and a dome light, adapting to evolving requirements.

- A single integrated tool enables comprehensive quality testing without major adjustments.

Smart and Efficient Quality Control

- Automatic parameter verification via an algorithm, independent of the operator.

- Eliminates manual visual inspections and reduces changeover times.

- Provides significant time savings while increasing productivity.

✔ Scalable digital wire-end detection ensures reliable and future-proof quality assurance.

| Type | Vision Inspection |

|---|