Komax - Wire Assembly Machine Omega 740

KMX-0336000

Omega 740 Cable Assembly Machine

Price on request

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Omega 740 cable assembly machine is designed to produce cable harnesses of varying complexity and can add connectors to one or both sides.

Key Features:

- Five module options: Up to five modules can be installed, allowing for the quick production of autonomous cable harnesses.

- Automated production: The Omega series is specifically built for the automated production of cable harnesses.

- Quality assurance: Regardless of the operator, a highly accurate force sensor monitors the insertion process for up to 36 different cables and ensures precise locking of the clamp component into the connector.

- Small part handling: The spindle drive supports the precise loading of even the smallest parts, which would otherwise be difficult to load manually.

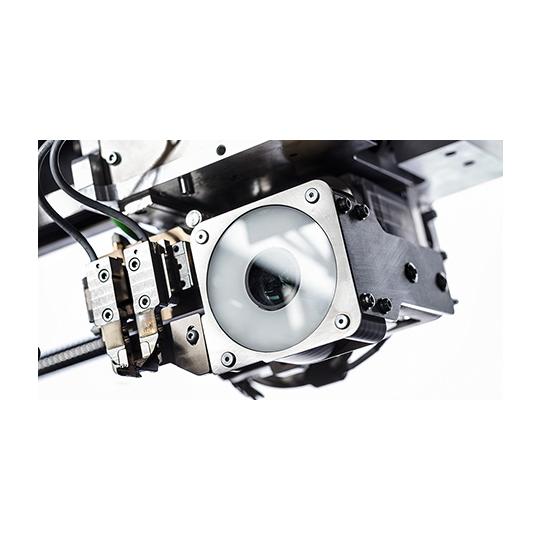

- Optional ACD precision monitoring: Further ensures quality and precision during the process.

- Optical terminal measurement system: For inserting various terminals.

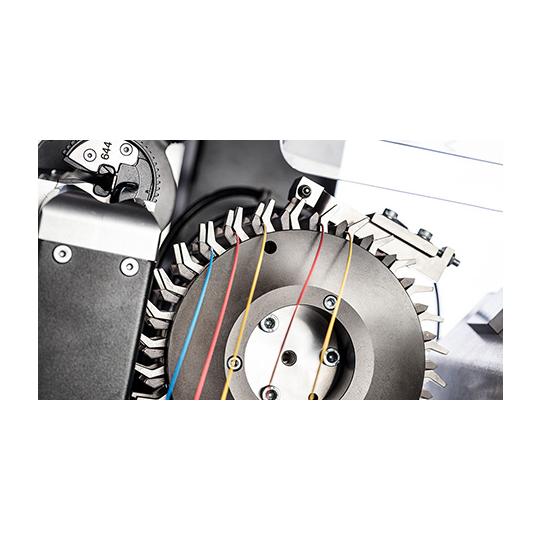

- Extensive cable changer: Supports up to 36 different cables.

- Three pairs of cutting blades: With optional ACD precision monitoring for enhanced accuracy.

- Untwisting module: Specifically designed to neutralize twisted cables.

- Integrated cable storage: Increases efficiency in production.

Specifications

| Piece output, single-sided and double-sided loading | 1.8 sec per insertion sequence (*) |

| Shortest wire length for single-sided loading | 240 mm |

| Shortest wire length for double-sided jumper connections | 300 – 560 mm (**) |

| Shortest wire length for complex loading | 300 – 780 mm (**) |

| Strip length | up to 25 mm |

| Wire cross-sections | 0.13 – 2.5 mm² (AWG 26 - 14) (***) |

| Outer wire diameter | Max. 4 mm |

| Usable transfer length | 1880 mm, up to five C1370 crimp modules |

| Usable transfer length extension | 1840 mm up to five additional C1370 crimp modules |

| Wire changer | Max. 36 wires (in increments of six wires) |

| Wire end storage | Rotary storage unit with a maximum of 30 storage spaces |

| Process monitoring (integrated) | Collision monitoring (block chambers), insertion force monitoring, terminal locking monitoring |

| Block feed | Carousel with pallets |

| Pallet system loading area | (W×H) 280 × 200 mm |

| Electrical connection | 3 × 208 – 480 V, 50/60 Hz/10 VA |

| Compressed air connection | 6 bar |

| Air usage | 20 m³/h |

The Omega 740 cable assembly machine is designed to produce cable harnesses of varying complexity and can add connectors to one or both sides.

Key Features:

- Five module options: Up to five modules can be installed, allowing for the quick production of autonomous cable harnesses.

- Automated production: The Omega series is specifically built for the automated production of cable harnesses.

- Quality assurance: Regardless of the operator, a highly accurate force sensor monitors the insertion process for up to 36 different cables and ensures precise locking of the clamp component into the connector.

- Small part handling: The spindle drive supports the precise loading of even the smallest parts, which would otherwise be difficult to load manually.

- Optional ACD precision monitoring: Further ensures quality and precision during the process.

- Optical terminal measurement system: For inserting various terminals.

- Extensive cable changer: Supports up to 36 different cables.

- Three pairs of cutting blades: With optional ACD precision monitoring for enhanced accuracy.

- Untwisting module: Specifically designed to neutralize twisted cables.

- Integrated cable storage: Increases efficiency in production.

| Type | With Wire Insertion |

|---|---|

| Max cross section (mm²) | 2.5 |