Komax - Wire Assembly Machine Zeta 630

KMX-0380000

Zeta 630: Increased Productivity in Switchboard Construction

Komax - Wire Assembly Machine Zeta 630

KMX-0380000

Zeta 630: Increased Productivity in Switchboard Construction

Price on request

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

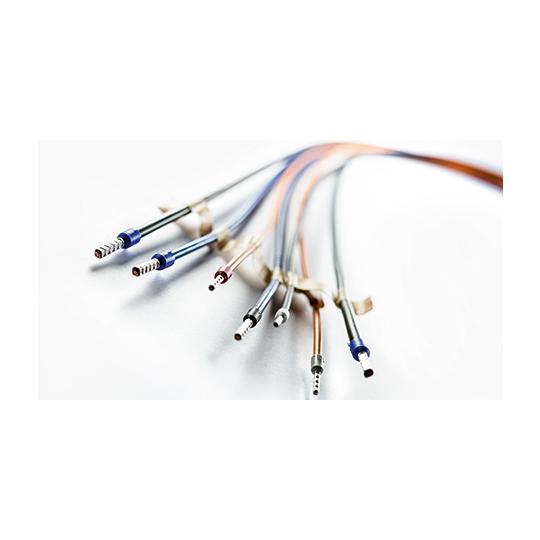

The Zeta 630 boosts productivity in switchboard construction by utilizing two process modules from batch size 1 and can handle up to 36 different cables via the cable changer.

Key Features:

- Just-in-time processing: Allows batch or series production without changeover for the assembly of various cables.

- Cable changer: The automatic cable changer offers 36 positions for efficient cable handling.

- Processing of terminal housings: The CM 1/5 GS module processes up to five different terminal housings, and the CM Duo module handles 4 mm² / 6 mm² housings.

- Precision cutting unit: Three specialized cutting blade sets ensure perfect processing of cross-sections from 0.22 to 6 mm².

- Automatic process settings: Processing parameters are automatically converted via TopConvert and sent directly to the machine through the Komax WPCS interface, eliminating manual programming.

- Processing of hard wires: Certain extremely hard, stiff wires may not be processed even if they fall within the specified cross-section range.

Additional Features:

- 36 cable variants available in the cable changer for maximum flexibility.

- Accurate processing with a high-quality cutting unit for sharp, precise results.

- Batch or series production without changeover, perfect for continuous production.

- Automatic marking system: Includes two inkjet markers for easy and fast cable labeling.

Specifications

| Length range with two-sided processing | 240 – 3000 mm standard tray / 240 – 5000 mm (optional) (*) |

| Length range with one-sided processing | 85 – 3000 mm standard tray / 85 – 5000 mm (optional) (*) |

| Stripping lengths | up to 25 mm |

| Wire cross sections | 0.22 – 6 mm² (AWG 24 – 10) (**) |

| Number of stations | 2 |

| Wire feed speed | Maximum of 10 m/s |

| Wire selector | Maximum of 36 cables (in increments of six cables) |

| Noise level | < 80 (without crimp modules) |

| Electrical connection | 3 × 208 V – 480 V 50/60 Hz; 3 kVA (basic machine) |

| Compressed-air connection | 5 – 6 bar |

| Air consumption | 7 m³/h (without modules) |

| Weight | about 1.700 kg |

The Zeta 630 boosts productivity in switchboard construction by utilizing two process modules from batch size 1 and can handle up to 36 different cables via the cable changer.

Key Features:

- Just-in-time processing: Allows batch or series production without changeover for the assembly of various cables.

- Cable changer: The automatic cable changer offers 36 positions for efficient cable handling.

- Processing of terminal housings: The CM 1/5 GS module processes up to five different terminal housings, and the CM Duo module handles 4 mm² / 6 mm² housings.

- Precision cutting unit: Three specialized cutting blade sets ensure perfect processing of cross-sections from 0.22 to 6 mm².

- Automatic process settings: Processing parameters are automatically converted via TopConvert and sent directly to the machine through the Komax WPCS interface, eliminating manual programming.

- Processing of hard wires: Certain extremely hard, stiff wires may not be processed even if they fall within the specified cross-section range.

Additional Features:

- 36 cable variants available in the cable changer for maximum flexibility.

- Accurate processing with a high-quality cutting unit for sharp, precise results.

- Batch or series production without changeover, perfect for continuous production.

- Automatic marking system: Includes two inkjet markers for easy and fast cable labeling.

| Type | With Tape Bundling |

|---|---|

| Max cross section (mm²) | 6 |