Komax - Wire Assembly Machine Zeta 630

KMX-0380000

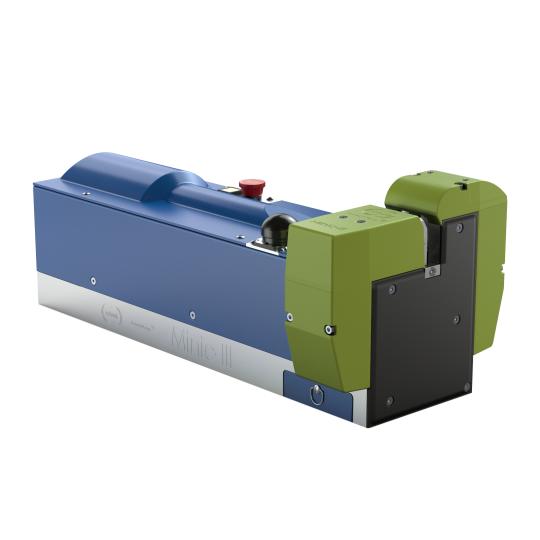

The Zeta 630 increases productivity in control cabinet construction with two process modules from batch size 1 and with up to 36 different wires in the wire changer.

Komax - Wire Assembly Machine Zeta 630

KMX-0380000

The Zeta 630 increases productivity in control cabinet construction with two process modules from batch size 1 and with up to 36 different wires in the wire changer.

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The wide variability of control cabinet construction requires many materials such as wire types, terminals or ferrules. The Zeta 630 allows just-in-time processing in batch or sequence production of various wires for cabinet building without changeover – thanks to the automatic wire changer with 36 positions, the CM 1/5 GS module for five different ferrules and the CM Duo for 4 mm² / 6 mm² sleeves.

With the three special blade pairs, cross sections of 0.22 to 6 mm² can be perfectly processed in sequence. The processing parameters are converted via TopConvert and sent automatically by the Komax WPCS interface directly to the machine without any manual programming effort.

Highlights

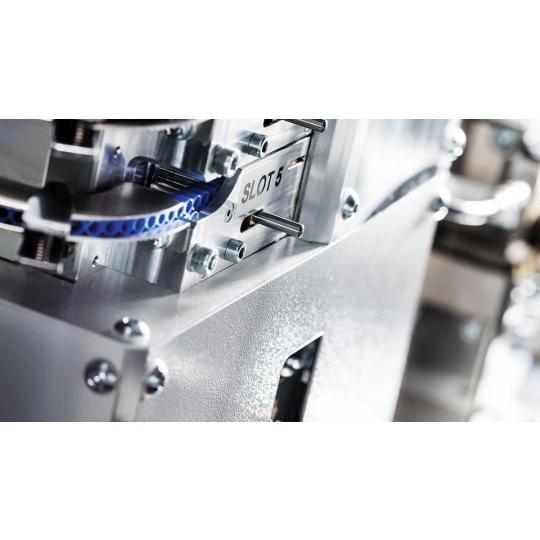

- 36 wire variants available in the wire changer: Automated processes reduce production time by up to 50 percent. The automatic wire changer provides up to 36 different wires without a changeover.

-

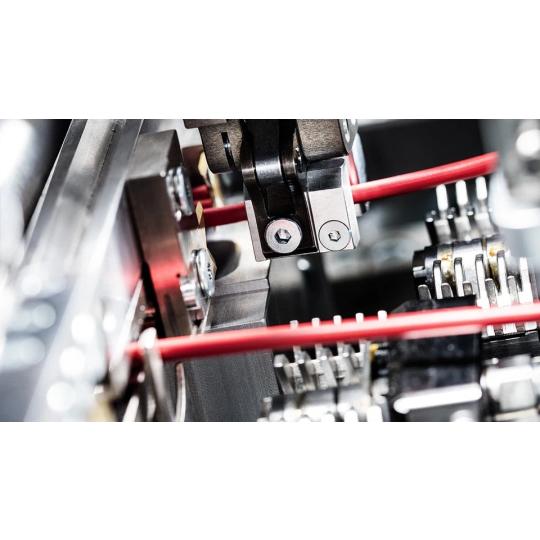

Precise processing with high-quality cutting unit: The cutting unit with three blade pairs processes cross-sections of 0.5 to 6 mm² perfectly in sequence. High-quality, durable blades enable high process speeds.

-

Batch or sequence production without changeover possible: The integrated bundler sorts the batches and fixes the appropriate wires with adhesive tape in a single process step. Even complex jobs can be completed without much effort.

-

Processing of up to 5 different ferrules: The CM 1/5 GS module processes up to five different ferrules. Reliable, fully automatic production ensures consistently high quality.

-

Automatic marking system with two inkjet markers: The automatic marking system for two different inkjet markers optimally labels the wires before completion for easy logistics and further processing.

Specifications

| Number of stations | 2 |

| Stripping Lengths | up to 25 mm |

| Wire Cross Sections | 0.22 – 6 mm² (AWG 24 – 10) |

| Wire Feed Speed | Maximum of 10 m/s |

| Wire selector | Maximum of 36 cables (in increments of six cables) |

Downloads

The wide variability of control cabinet construction requires many materials such as wire types, terminals or ferrules. The Zeta 630 allows just-in-time processing in batch or sequence production of various wires for cabinet building without changeover – thanks to the automatic wire changer with 36 positions, the CM 1/5 GS module for five different ferrules and the CM Duo for 4 mm² / 6 mm² sleeves.

With the three special blade pairs, cross sections of 0.22 to 6 mm² can be perfectly processed in sequence. The processing parameters are converted via TopConvert and sent automatically by the Komax WPCS interface directly to the machine without any manual programming effort.

Highlights

- 36 wire variants available in the wire changer: Automated processes reduce production time by up to 50 percent. The automatic wire changer provides up to 36 different wires without a changeover.

-

Precise processing with high-quality cutting unit: The cutting unit with three blade pairs processes cross-sections of 0.5 to 6 mm² perfectly in sequence. High-quality, durable blades enable high process speeds.

-

Batch or sequence production without changeover possible: The integrated bundler sorts the batches and fixes the appropriate wires with adhesive tape in a single process step. Even complex jobs can be completed without much effort.

-

Processing of up to 5 different ferrules: The CM 1/5 GS module processes up to five different ferrules. Reliable, fully automatic production ensures consistently high quality.

-

Automatic marking system with two inkjet markers: The automatic marking system for two different inkjet markers optimally labels the wires before completion for easy logistics and further processing.

| Type | |

|---|---|

| Max cross section (mm²) |