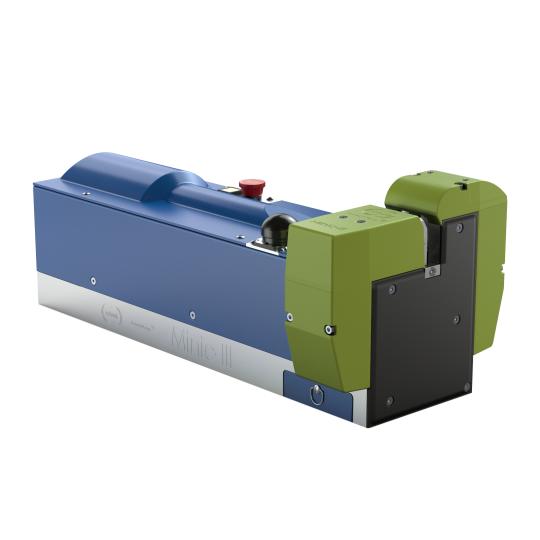

Komax - Wire Assembly Machine Zeta 650

KMX-0338000

Zeta 650 can process up to 36 wires without changeover, from batch size 1 and just-in-time.

Komax - Wire Assembly Machine Zeta 650

KMX-0338000

Zeta 650 can process up to 36 wires without changeover, from batch size 1 and just-in-time.

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

Thanks to the eight process modules, the Zeta 650 can process up to 36 cables without changeover, from batch size 1, and just-in-time, ensuring higher productivity and efficiency.

Key Features:

- Fully automated cable assembly: The Zeta 650 assembles the required cables fully automatically on eight process modules from A to Z, speeding up production and increasing accuracy.

- Just-in-time and batch processing: The machine processes cables without changeover, making it ideal for both batch and series production.

- Easy processing parameters: Processing data can be easily converted via TopConvert and automatically sent to the machine via the Komax WPCS interface, eliminating the need for manual article programming.

- Efficiency and error-free processing: With automatic data transfer, the feed and processing are flawless and highly efficient.

- Flexibility and scalability: The machine can handle 36 cables of various cross-sections and is suitable for a wide range of cable types.

- Specific features:

- Three pairs of cutting blades with optional ACD precision monitoring.

- Sorting and bundling of cable bundles in one process step.

- Automatic cable changer for up to 36 cables.

- High performance with three shuttles operating in parallel.

- Optional tube labeling for bundled cables.

Specifications

| Stripping lengths | up to 25 mm |

| Wire cross sections | 0.22 – 6 mm² (AWG24 – AWG10) (**) |

| Useable transfer length Zeta 640 | 1.880 mm, up to 5 crimp modules C1370 |

| Useable transfer length extension | 1.720 m, up to 5 additional crimp modules C1370 |

| Wire feed speed | Maximum of 10 m/s |

| Wire selector | Maximum of 36 cables (in increments of six cables) |

| Noise level | < 75 dB (without crimp modules) |

| Electrical connection | 3 × 208 – 480 V 50/60 Hz; 10 kVA (basic machine) |

| Compressed-air connection | 5 – 6 bar |

| Air consumption | 12 m³/h, (without modules) |

| Weight | approx. 2.600 kg |

Downloads

Thanks to the eight process modules, the Zeta 650 can process up to 36 cables without changeover, from batch size 1, and just-in-time, ensuring higher productivity and efficiency.

Key Features:

- Fully automated cable assembly: The Zeta 650 assembles the required cables fully automatically on eight process modules from A to Z, speeding up production and increasing accuracy.

- Just-in-time and batch processing: The machine processes cables without changeover, making it ideal for both batch and series production.

- Easy processing parameters: Processing data can be easily converted via TopConvert and automatically sent to the machine via the Komax WPCS interface, eliminating the need for manual article programming.

- Efficiency and error-free processing: With automatic data transfer, the feed and processing are flawless and highly efficient.

- Flexibility and scalability: The machine can handle 36 cables of various cross-sections and is suitable for a wide range of cable types.

- Specific features:

- Three pairs of cutting blades with optional ACD precision monitoring.

- Sorting and bundling of cable bundles in one process step.

- Automatic cable changer for up to 36 cables.

- High performance with three shuttles operating in parallel.

- Optional tube labeling for bundled cables.

| Type | With Tape Bundling |

|---|---|

| Max cross section (mm²) | 6 |