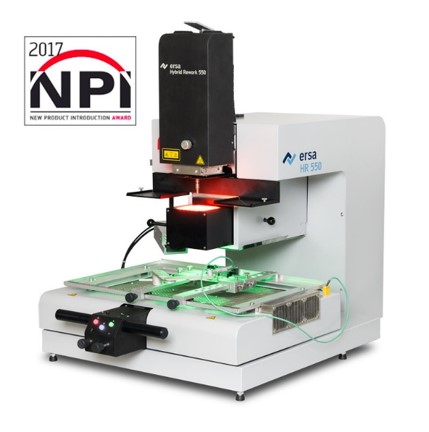

ERSA HR550 – DE IDEALE OPLOSSING VOOR FLEXIBEL EN BETROUWBAAR SMD REPAIR

31-01-2019

Dit complete station is inclusief 1500 W hybride topheater, 3 grote IR zones onderwarmte en geïntegreerde vacuüm pipet voor plaatsing en pickup. Door de bekende HRSoft 2 en de “Enchanced Visual Assistent” (EVA) wordt u door het gehele proces begeleid en bedient u de HR550 als een ervaren operator. SMD Repair was nog nooit zo eenvoudig en betrouwbaar.

Interesse in een demo? Contact onze specialist Roy Van Alphen.

Roy van Alphen

T +32(0)496/42.10.36