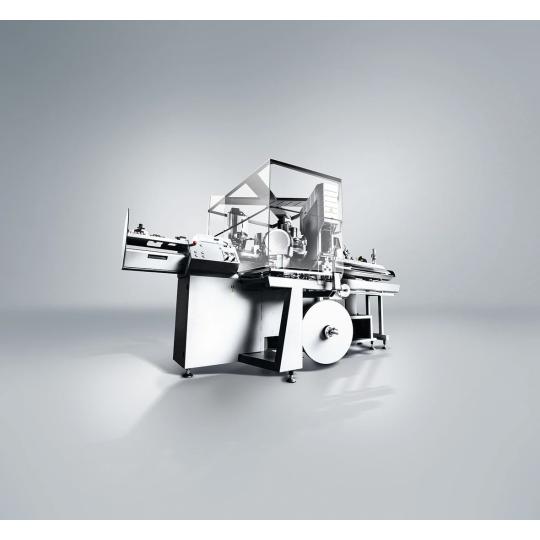

Komax - Fully Automatic Wire Processing Machine Alpha 530

KMX-0341000

Fully Automated Cable Processing Machine for Dual-Sided Crimping and Sealing

Komax - Fully Automatic Wire Processing Machine Alpha 530

KMX-0341000

Fully Automated Cable Processing Machine for Dual-Sided Crimping and Sealing

Need a quote, installation, or training?

Call +32 (0)14 42 44 01 or contact us

Description

The Alpha 530 fully automated cable processing machine for dual-sided crimping and sealing meets high-quality standards for cable cross-sections from 0.13 – 6 mm². Larger cable cross-sections can be processed upon request, and Komax offers feasibility tests to pre-test cables, especially very hard or stiff cables that may not be processed even if they fall within the specifications.

Key Features:

- Flexible configuration: The Alpha 530 offers capabilities for special and complex applications such as dual crimping, terminal and wire end lug insertion, as well as twisting and tinning of strands.

- Short distances between stations: The machine features short distances between crimping, cable, and cutting stations, increasing productivity.

- LED-lit work zones: LED lighting in the work zones improves visibility and safety.

- Intuitive user interface: The sequential and individually configurable interface enhances ease of use and quick setup.

- Short setup and changeover times: The machine offers fast changeover times, boosting efficiency even with variable production.

- Quality assurance: Crimp force monitoring (CFA+/CFA) is built in for quality control, and optional precision monitoring (ACD) can be added to detect even the smallest contact between the blade and the conductor during the stripping process.

- Convenient and safe storage: Tools are easily accessible in a practical drawer beneath the cable input, and finished cables can be safely stored in a steel drawer.

- Efficiency: The reliable and fast belt drive provides a feed speed of 9m/s, contributing to high productivity.

Specifications

| Wire cross sections | 0.13 – 6 mm² (AWG 26 – 10) |

| Wire draw-in speed | max. 9 m/s belt drive |

| Outer diameter of conductor | max. 5,1 mm |

| Length range | 60 – 65.000 mm / optional 30 – 60 mm (Wire length tolerance ± (0.2% + 1 mm)) |

| Full stripping | 0.1 – 18 mm / optional up to 29 mm |

| Half stripping | 15.5 mm / optional up to 35 mm |

| Crimp force | 1 – 22 kN |

| Process modules side 1/ 2 | 2 / 2 |

| Noise level | < 80 dB (without crimp tool) |

| Electrical connection | 3 × 208 – 480 V / 50 – 60 Hz / 5.6 k VA |

| Compressed air connection | 5 – 8 bar (73 – 116 psi.) |

| Air consumption Crimp / Crimp | < 7 m³/h |

| Air consumption Seal crimp /Seal crimp | < 11 m³/h |

| Weight (incl. 2 crimp modules) | 1.300 kg |

Downloads

The Alpha 530 fully automated cable processing machine for dual-sided crimping and sealing meets high-quality standards for cable cross-sections from 0.13 – 6 mm². Larger cable cross-sections can be processed upon request, and Komax offers feasibility tests to pre-test cables, especially very hard or stiff cables that may not be processed even if they fall within the specifications.

Key Features:

- Flexible configuration: The Alpha 530 offers capabilities for special and complex applications such as dual crimping, terminal and wire end lug insertion, as well as twisting and tinning of strands.

- Short distances between stations: The machine features short distances between crimping, cable, and cutting stations, increasing productivity.

- LED-lit work zones: LED lighting in the work zones improves visibility and safety.

- Intuitive user interface: The sequential and individually configurable interface enhances ease of use and quick setup.

- Short setup and changeover times: The machine offers fast changeover times, boosting efficiency even with variable production.

- Quality assurance: Crimp force monitoring (CFA+/CFA) is built in for quality control, and optional precision monitoring (ACD) can be added to detect even the smallest contact between the blade and the conductor during the stripping process.

- Convenient and safe storage: Tools are easily accessible in a practical drawer beneath the cable input, and finished cables can be safely stored in a steel drawer.

- Efficiency: The reliable and fast belt drive provides a feed speed of 9m/s, contributing to high productivity.

| Type | Crimp To Crimp |

|---|---|

| Max cross section (mm²) | 6 |