From challenges to solutions – The collaboration between Ascos & Smans

Ascos, a specialist in electronics development, manufacturing, PCB assembly and system assembly, significantly strengthened its position in the Dutch market by working with Smans, a leading supplier of assembly lines and production machines. This case study describes the challenges Ascos faced, the solutions Smans provided, and the impressive results of this collaboration.

Ascos is a dynamic company with a small, close-knit team of seven employees. Led by Young Kampshoff and Mark Sterk, Ascos focuses on offering flexible, fast and high-quality production services to their customers. Despite its modest size, Ascos offers a full process, from electronics development to system assembly, making them stand out in a competitive market.

Challenges in the market

Ascos faced some significant challenges in the rapidly changing electronics industry. The main issues were:

- Delivery times and flexibility: Ascos’ customers required shorter lead times and more flexibility. Delivery times were sometimes up to 10 weeks, which was a barrier to their customers’ growth.

- Staff shortage: Finding technically skilled staff proved difficult. Ascos had to provide its own training to close this gap.

- Production costs: The rising cost of components forced Ascos to find creative solutions to reduce production costs without compromising on quality.

Investment in a new assembly line

To address these challenges, Ascos decided to invest in its own assembly line. Smans was chosen because of their listening ear, thinking along, knowledge, extensive range and personal approach.

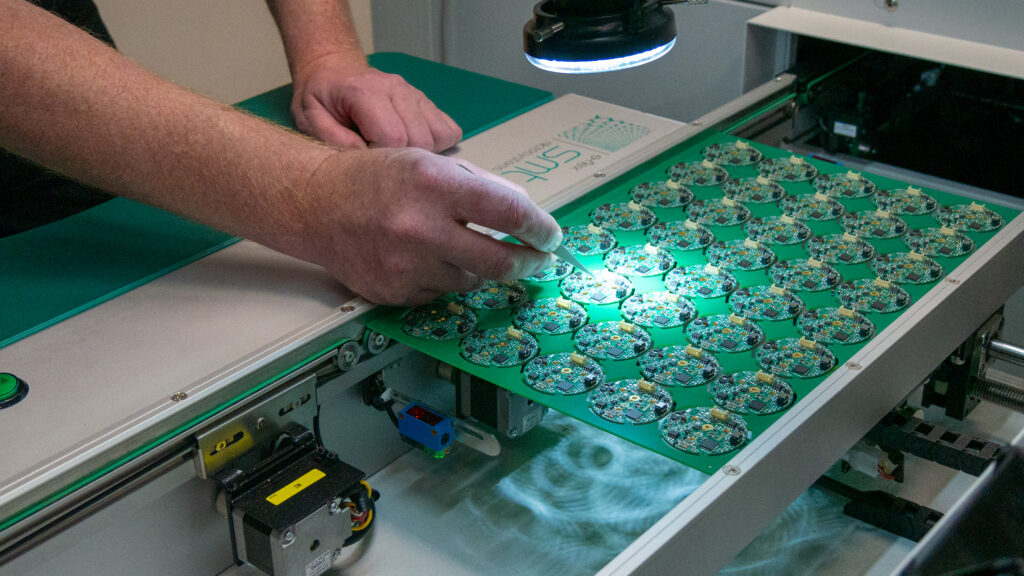

The new assembly line, consisting of the Europlacer Screen printer EP710. For SMT Pick & Place, the Hanwha Chip Mounter SM482 was chosen. It offered the precision and speed Ascos needed to remain competitive. The ERSA HF 3/14e complemented the whole to ensure perfect soldering results.

This investment also required organisational changes, such as moving to larger premises and optimising inventory management to support increased component procurement.

Benefits of the new assembly line

The new assembly line has brought several benefits to Ascos:

- Improved flexibility and productivity: The new line allows Ascos to produce more flexibly and efficiently, resulting in increased output and shorter lead times. For example, they can now deliver within 4-5 weeks for normal productions and even within 1-2 weeks for prototypes.

- Increased quality: The precision of the new machines has resulted in higher product quality, which is important for the high-end products Ascos supplies.

- Cost efficiency through value engineering: Ascos can reduce production costs through creative solutions such as component substitution and design optimisation. For example, by replacing expensive components with cheaper alternatives that offer the same quality, and by redesigning PCBs to make assembly faster and easier. Bulk purchasing of components also provides significant cost savings.

These benefits enable Ascos to offer their customers flexible lead times, improve product quality, and reduce production costs, making them more competitive in the market.

Collaboration with Smans

The collaboration with Smans began through a recommendation from a business friend. Smans stood out for their ability to meet both Ascos’ current and future production needs without sacrificing quality.

They offered a new line specifically designed for serial production, which could work quickly and very precisely. Moreover, this line is relatively compact and easily expandable with, for example, a chip shooter or an SM481 machine, making it easy to expand capacity.

The personal and professional guidance provided by Aad Vermaat of Smans was a crucial factor in the decision to choose Smans. Smans also offered extensive support in installing and using the machines.

Thanks to Smans’ help, Ascos was able to maximise the use of their production line and quickly resolve any start-up problems.

Results and future plans

Working with Smans has enabled Ascos to fulfil their growth ambitions without compromising on flexibility and quality. They can now produce faster and more efficiently, which benefits their customers.

For the future, Ascos is planning a move to larger premises and will invest in new machinery for process optimisation. They remain focused on organic growth and serving specific customers such as start-ups and small SMEs, with a focus on long-term partnerships and joint development.

Would you like to discuss the possibilities of having your own assembly line at your company? Then feel free to contact Smans for an appointment.